The Reliable Semi-Automatic Shotgun Story

Flip open most any catalog or view most any manufacturer's website, and you will find that they offer the “most reliable shotgun in the world.” Everyone sells “that model,” or claims to. Someone isn't telling the truth. Well, most of them aren't telling the strict truth, for the most reliable can be only one shotgun. It is along the lines of “All horse thieves are Democrats, but not all Democrats are horse thieves.” Some gun companies could save the marketing money by splitting the costs of the ad-copy with the competition, for many say essentially the same things, every year.

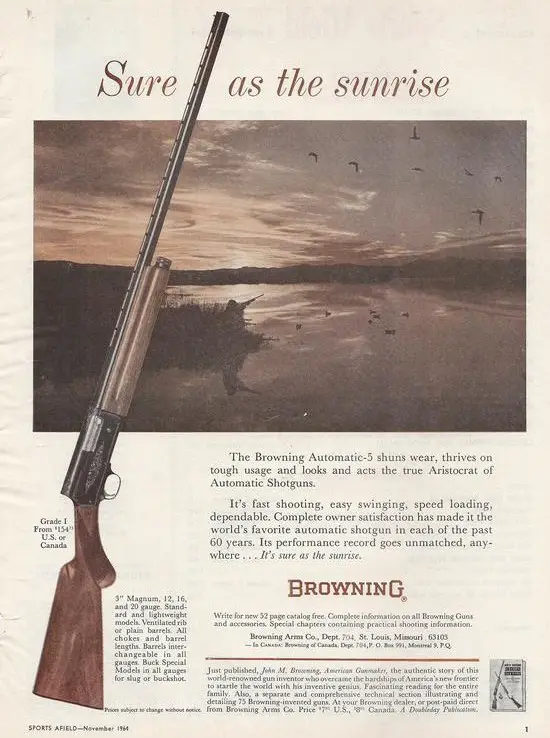

About 120 years ago, John M. Browning designed his Automatic-Five. No shotgun since is any more reliable, as far as I'm concerned. My Great-Grandfather, who I knew well, used his Browning-licensed Remington Model 11 year-round for most of his long life. My grandfather had one firearm: a Browning Light Twelve. As far as the “do it all shotgun,” that was it . . . it had to be, for that was the only gun he ever had, and it was used for everything a shotgun could be used for around Chebanse, Illinois. It still runs beautifully today. My Dad, until he became gas-gun enlightened, used a standardweight A-5 12 gauge, plain barrel, that he bought used. It was flawless, essentially.

One fateful day, Dad decided to use the then newer 1-1/2 oz. “Baby Magnum” loads in his old standardweight A-5. One shot was all it took, for that cracked the mainspring tube. It took a few attempts for Hank Williams of Hank Williams Sporting Goods to find the problem, but that was it. After that was replaced, there were no problems for decades thereafter, and no problems even today. Considering that the good old days were also the days of paper hulls that were prone to swelling, the A-5 is the most reliable shotgun there is, with a few caveats.

The “light load setting” meant 1-1/8 oz. 1200 fps loads, the “heavy setting” was 1-1/4 oz. 1330 fps loads. That was about all there was, back when I was growing up. The A-5 was and is about as reliable as it gets, if you used it as suggested. Of course, we don't like to read directions, much less follow them. We also have the misguided idea today that a 12 gauge that cycles 1 oz. loads or 7/8 oz. loads is more reliable than a semi-auto that doesn't. Nothing could be further from the truth: it just means that it is more reliable with 7/8 oz. or 1 ounce loads. If this idea was remotely close to being true, then the most reliable shotgun would be a 28 gauge of some sort.

While down in Argentina years back one of the bird boys asked if I liked A-5s. Of course, the answer was yes. He proudly brought out his A-5; to say it looked rode hard and put away wet would be an understatement. He asked if I wanted to try it and I said, “Of course.” Now, that A-5 kicked. It practically tore my shoulder off. I popped off the barrel and there was no bronze friction piece, no bevel ring, no nothing. Just a barrel on a spring. I asked if he understood that some critical parts were missing and he said, “The little pieces? Don't need them-- threw them away ten years ago.” I mentioned that he'd likely have a lot more comfortable gun with those little pieces installed properly. He said, “No. This is the best. This is the best gun ever. It never jam. It never jam.” I didn't doubt him. That A-5 cycled just fine, even though the back of the receiver was pounded mercilessly with every shot and apparently had been enduring that for years.

Many shotguns are comparatively fragile on the high payload end of things. I've had several Browning Golds myself, but I always preferred the Browning-Beretta B-80s. My Dad loved his Gold 20 gauge, but like of shotguns, the trigger was miserably heavy and the safety was next to impossible to get off with your forefinger: it was a 20 lb. safety or so. Both of those problems were addressed by gunsmith Dave Metcalf. What wasn't addressed with the fragility of the gun with heavy loads. A few 1-1/2 oz. turkey loads, and the fun was disabled, thanks to a shattered bolt buffer. It was an easy, inexpensive replacement.

WHAT HAPPENED TO THE A-5, THE MOST RELIABLE SEMI-AUTO SHOTGUN EVER?

Above: Dad, Keith, Kevin, Randy. Auto-Fives took all of these wild roosters. Frisco, Kelsey, and Rocky found them.

As it turns out, people don't actually buy what they claim they want. They tend to buy cheaper, even if cheaper is a downgrade in build quality. That's part of what happened to A-5 sales: the public wanted cheaper to make and buy shotguns, lighter shotguns, shotguns that were easier for home gunsmithing, and of course, what they think is less recoil. While it took a lot of work to design the very heavy A-5 Magnum Twelve, a 3-1/2 inch Automatic-Five would have been a true beast of a shotgun. As is, the Miroku A-5 models already got heavier and heavier.

No

semi-automatic shotgun is maintenance free, not even the A-5, but we

like to shoot things until they no longer work. The Remington 1100

series remains the best-selling semi-automatic shotgun in the history

of the world by a large margin. A fellow whose handle is

“Northeastm1a” compiled a very comprehensive list

in 2007 showing

how the 1100 can be a 300,000 round gun when properly maintained. It

should make us wonder why we obsess over the cost of guns so much, as

300,000 rounds of high-quality target ammo alone will run you over

$100,000.

1100

Longevity

My

first 12 ga 1100 receiver lasted almost 20 yrs of hard, registered

shooting (over 50,000 rds since 1981) ; plus easily four times that

number in non-registered practice shooting. 250,000 rds is a

conservative estimate. It was probably closer to 300,000 rds.

The

magazine tube finally broke off the receiver one day when I took

apart that 1100 to clean it. It's barrel lasted another three years

and probably 25,000 to 30,000 rds after the receiver was junked,

before its extension developed a hairline crack near the locking lug

recess.

It's bolt lasted another two seasons beyond that

before it, too developed a crack near the extractor recess. The

original 1981 firing pin after 300,000 estimated rounds is still

going strong, though I have probably replaced two dozen firing pin

RETRACTOR SPRINGS that broke around the pin during all that time.

The trick to 1100 longevity is as follows:

1. Change

the action spring in the stock every 10,000 rds

(some say 5,000,

but I've been getting 20-25 yrs of service life

going every

10,000) This is far more important than changing the buffer disc at

the back of the bolt and prevents bolt to receiver impact (from the

spring tension offering resistance

against the bolt's reward

travel) A new action spring is 15" long from the factory before

it is installed and compressed. 14-1/2" means - it's time to

replace.

2. GREASE the top, exterior surface of the barrel

extension

doing this, forms a cheap, "gel" cushion that

soaks up the metal to metal impact of the top of the barrel extension

against

the inner surface of the receiver top caused by

vibrations during firing.

3. Grease the bottom flat

surface of the outside of the barrel that presses against the forearm

support (spring steel bushing)

doing so will DOUBLE the service

life of that fragile part.

4. Grease the surfaces of the

receiver where the forend support bites into - again reduces some

wear and soaks up vibrations

5. After about 100,000 rounds -

switch to a locking lug marked with an etched "L" (for

large, or long). This takes up the space worn by the friction of the

standard lug against the barrel extension over time. Once that recess

becomes sufficiently worn, you will get more "peen" impact

of the locking lug as its fit becomes loosened and is allowed to

whack the barrel extension harder due to the increased space it has

to move in.

Once you do this, you're good for about another

100,000 rds.

After that, you may need a new barrel. Tell tale

signs of worn locking lug recesses include: primers backing out of

factory shells. I've worn at least two barrels this way and have

replaced a few for other people as well over the years.

6.

Inspect the gas cylinder for "ridge burrs" Ridge burrs form

from the ring friction from the action bar sleeve driving everything

home, hard. Smoothing them out, carefully prevents "train

wrecking" of the action bar/action bar sleeve/bolt assembly -

all that inertia driven by the action spring slamming the piston and

piston seal, home into the "collar" or more properly, GAS

CYLINDER - driving the rings into the cylinder - hard - and then

having the rings get "tripped up" on ridge burrs that

formed inside the gas cylinder. Smoothing out those burrs - will

DOUBLE the service life of the piston and piston seal.

7.DO

NOT make a habit of using STEEL WOOL or metal abrasives on the

magazine tube to clean it. Doing so, WILL over time, reduce the OD

(outside diameter) of the mag tube enough to cause, loose ring fit

and hence, GAS LOSS leading to irreparable functioning problems.

Instead, use rags and solvents, wipe dry and put a drop or two of

BREAK FREE on the tube. If you have enough caked on crud to scrape

off, use a PLASTIC edged tool, like a disposable plastic picnic knife

or other similar NON METAL MARRING plastic tool (expired cut up

credit card or something) to scrape carbon residue from the tube.

8. ALWAYS put ONE drop of BREAK FREE or similar lube on the

center of the firing pin spring where it is stressed the most.

9.

Using a Q-TIP - NOT your fingers - GREASE the underside, flat

surfaces of the receiver rails that contact the front part of the

link (the "wing" part of the link) Doing this will reduce

friction wear and lengthen service life of both the link, and the

receiver. Also, new links should be polished, deburred and lubed to

prevent burr "snags" during cycling-which leads to broken

links and greasing the rails reduces friction wear and the thinning

out of the rails which, over time, allows for more MOVEMENT of the

link during the firing cycle, which leads to premature link

breakage.

10. Lube the white spots on the action bar and

grease the "fracture point" on the right leg of the action

bar.

Replace the link if not broken - after 5,000 shots

before entering a serious tournament; replace the firing pin

retractor spring at 5,000; the extractor at 10,000, the action spring

at 10,000, the piston rings at 5,000 and the forend supports and

rubber viton barrel seal at 3,000 rds to enhance reliability.

Also, when removing the recoil pad, stock or action spring -

DO NOT bear down with your weight against the butt, and the mag tube

end against the floor - that will stress the mag tube and lead to

prematurely separating the mag tube from the receiver, causing it to

be junked.

Following these proven steps along with regular

cleaning, and your 1100 is highly unlikely to break down on the line.

Mine has not broken down at a trap shoot in over ten years.

The

1100 can outlast a Perazzi or K-80 between parts breakages and will

be on the spot repairable in minutes if not, seconds.

Tips

acquired over 20 yrs from Remington gunsmiths, service techs and

employee-shooters at the Grand and the old Remington Gun Club to

include: Amerigo Pagliaroli (fmr. mgr: Remington Gun Club & CTA

Hall of Fame), "Tex" Cavaina (Sr. Remington 1100 gunsmith);

the late Floyd "Jiggs" Cochran (Remington ballistician; CTA

Hall of Fame); the late Dick Baldwin, (ATA Hall of Fame) and Daniel

Buhan, (fmr. trap mechanic of the Remington Gun Club & 1100

shooter) among others.

Above: A girl, a goose, and an 11-87.

WHAT

HAPPENED TO THE 1100, THE SOFTEST SHOOTING, LONGEST-LASTING SHOTGUN

FROM 1963 ONWARD?

Well, nothing: it is still in production in Ilion, New York, and still selling. Times have changed, though, as my once-beloved dwell meter, timing light, and spoke wrench aren't used much today. People want simpler things that require as little cleaning and ordinary maintenance as possible. While steel is roughly four times as strong as alloy, it takes 4-5 times as much time to machine. The trend has been to use alloy receivers to save on machining costs, along with more and more plastic. Remington themselves went the alloy receiver route with their Versa-Max. While Browning B-80s (barrels by Beretta) were offered with steel or alloy receivers, B-80 production ceased in 1987. The Browning B-80 (and Beretta 302 / 303 series) are still among my favorite gas guns, even though the 3 inch chambered guns struggle with target loads. They are simple actions and they don't break. For all-load reliability, you need two barrels, a 2-3/4 inch and a 3 inch. Folks aren't all that keen on that idea today. The B-80 and Beretta 303 helped popularize shim adjustments for drop: something many people like, but not present on Automatic-Five and 1100 series models.

THE SACRIFICIAL PART

This may sound like engineer-speak, and I suppose it is. The Browning / Brownchester Active Valve guns have the Active Valve as a weak link. It will break, sooner or later, and the only solution is to have a spare in your range bag. Bolt buffer problems, associated with the old Super-X Model One, are there on some Beretta 391s, along with well-known shell elevator problems. The Gold / Silver Browning models break buffers as well, but it is an easy repair. If you are a consumer, your gun just broke. If you are an engineer tasked with getting the cost out of the gun, it is a sacrificial part. I like what Bruce Buck had to say about gas guns, in what Bruce calls the basic Technoidal gas gun primary rule: “Gas guns are like sheep. They know when they are alone and they don’t like it.” If your gun's shear pin is called a buffer or an Active valve, carry a spare.

TODAY

The $400 standard Grade I Browning Automatic-Five of 1975 is about $1910 in 2020 dollars. Though we all seem to enjoy grousing about gun prices, new gun prices are quite a bargain today compared to property taxes, health care, or new car prices. For good quality shotguns, the warranties are better, the customer service is better, and communication is better. When I was growing up, long distance phone calls were avoided, a once a year event to family and special friends, and lacking a long distance phone call, the basic form of communication was to write a proper letter, put a stamp on its envelope, and wait. And wait some more.

High-quality ammunition is better, in this case meaning more reliable, and that has made autoloading shotguns as a class more reliable as well. We can hardly expect anything to be more reliable than what we feed it. Three of my favorite shotguns come from Italy, the United States, and Turkey. Aside from waterfowl, my tastes generally run towards walnut and polished blue. That's your choice, of course, as is your personal tolerance for gun weight, maintenance and recoil.

Above: L4S Grey Hunter, L4S Initial Hunter with a pair of Illinois corn-fed roosters.

The Fabarm L4S Hunter series is what I've used for pheasant opener every year for the last five years. Back in 2015, I wrote, “The L4S has a lively, responsive feel that most 12 gauge autoloaders lack. Nothing rattles, no loose forearm syndrome, and it has a very solid, steady feel that the pogo-stick and “springy stock thing” autoloaders sadly lack. Based on trigger quality, barrel quality, choke quality, generously chrome plated action parts, and flawless assembly, the L4S is the most satisfying 12 gauge autoloader I've shot in decades. Add in its dashing good looks and the surprisingly low price, the L4S Initial Hunter easily gets my vote for Shotgun of the Year.” The gas-operated Fabarm L4S at 6-3/4 lbs. is my version of the ideal pheasant-bagger.

The Remington V3 synthetic, with a 26 inch barrel, is my version of an ideal affordable, reliable, do-almost-anything shotgun. It is Remington's best autoloader and does well essentially everywhere, with extremely low recoil and a written lifetime warranty to boot. I've been using V3's since 2015 as well.

The Retay Masai Mara is a model that I first started using in 2017, the “Better Benelli Than Benelli.” With an improved inertia action (the patented Inertia Plus action) in all Retay USA models, it loads easier than most Benelli and other inertia models, eliminating both the notorious Benelli Click and the “Benelli Thumb.” The Retay “Air King” model adds speed unloading and a 3-1/2 inch chamber and has already been extremely well-received. Retays also shoot where they are pointed.

One (or all) of these models will make you very happy. All of them have shims available for drop and cast, and the written warranties are at least five years. For left-handed shooters, you'll be glad to know that both the Fabarm L4S and Fabarm XLR5 Waterfowler are available in left-hand models.

For

more info, see:

Copyright 2020 by Randy Wakeman. All Rights Reserved.