Hornady Changes Gun Care for Good

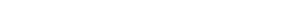

According several gun manufacturers, the top so-called firearm problem is rust and corrosion. Rust and corrosion costs the United States 1 Trillion dollars annually. The top threat to drinking water is rust. Rust is hardly limited to firearms.

A few years back, a fellow who calls himself “rancidcrabtree1964” and also DIY_guy whose primary interest is bow hunting did a comprehensive test of forty-six different gun care products, looking for how they inhibited corrosion. The testing was not performed on firearms, however, but on sheet metal. Left out in the rain, only three products did an exemplary job at stopping rust on the sheet metal “Board Number 1”: Hornady One Shot, WD-40 Specialist, and Rust Prevent. On corrosion Board Number 2: Hornady One Shot, Frog Lube, and WD Specialist were the top performers.

A static coefficient of friction test was conducted and Hornady One Shot again was a top performer, with only Barricade edging it out in “Static Coefficient Test #2.” Again, no firearms were used in this evaluation and no consideration was given to kinetic frictiom or actual firearm performance. Years ago, I changed to Breakfree CLP for most of my firearms care and never looked back. Now, it is going to be Hornady One Shot for good.

Here's why: Hornady One Shot exceeds the NATO minimum load carrying specification by six times. It is heat and cold resistant from 400 degrees F. to -40 degrees F. This is what Hornady has to say:

DynaGlide Plus® Micro-Layered Tri-Boundary Dry-Films Conditioners/lubricants offer a broad

spectrum of protection not found in other gun conditioner or lubricant products:

• Heat resistant to 400-plus° (204 plus °C)

• High load carrying capacities (metal to metals pressure)

• Hazardous cleaners and lubricants are not used or needed

• Prevents Burnt Carbon and Lead build-ups

• Humidity and Moisture repelling and displacing

• Prevents the accumulation of residues, debris, gunk build-up associated with oil or silicone lubricants.

• Non-Toxic non-hazardous protective films

• Withstands 400 hours of Military salt spray corrosion test

• Maintains a sustainable near new and perfect firearm condition

• Severely restricts abrasive and erosive wear action from burnt powders and oils contaminants

• Allows a soft cleaning patch to “push” out lead residues without using abrasive wire brushes

• Prevents build ups of contaminants compressed into metals by gas and load pressure

• Reduced resistance to contaminant build up offers sustainable shooting velocity and accuracy

• Greatly reduces or eliminates frequent gas port adjustments in semi-auto and automatic firearms

The longstanding problem is with gun oil build-up. Gun manufacturers continually warn about over-lubrication and often tell you to shoot their firearms completely dry in cold weather. A dry firearm is, of course, prone to corrosion, high friction, and accelerated wear, but many consider that not only palatable but preferable compared to constant jams. The constant warning about over-lubrication is exactly because most gun oils attract and retain crud. No lube, less crud, but unfortunately more wear, more propensity towards corrosion.

The friction and wear may not be pronounced in a bolt-action rifle, but for semi-automatic shotguns, rifles, and pistols, gummed-up actions and congealed oils are a problem. You can only blow hot gas full of particulate matter onto actions for so long before things get sluggish. I've spend most of my life cleaning “self-cleaning” actions. Most of them are anything but.

How often have you heard, “I cleaned it and lubed it, but it still jams!” It is really hard telling what someone's version of cleaning and lubing might be, what they are using, or how they are using it. Gas pistons get full of of crud quickly, and gas ports close up quicker than you might think. Gas ports are routinely ignored, it is easy to forget about them, but eventually your gun doesn't cycle light loads anymore and we don't like it.

To be sure, there are some applications where we want high friction, high heat, and high wear. I wouldn't suggest using Hornady One Shot on your brake pads. A good oil lubricant has to have film thickness greater than the sum of the maximum heights of the surface irregularities. That's the problem, for the thicker the film the more crud it can attract and hold.

In the case of boundary lubrication featured in Hornady One Shot, the lubricant film thickness is smaller than than the sum of the maximum heights of the surface irregularities. That is why Hornady One Shot retains far less unwanted crud and debris than petroleum lubricants, and that's what makes it a far better product for semi-automatic firearms. It makes pump guns smoother and slicker functioning as well, and once you try it you won't use anything else.

For more information, see https://www.hornady.com/reloading/case-care/lubes-and-cleaners/one-shot-cleaners .

Copyright 2018 by Randy Wakeman. All Rights Reserved.