The Eternal Battle of Gas versus Recoil Autoloading Shotguns

A common area of discussion regarding autoloading shotguns is the “which is better” debate, gas-operated or recoil operated. Naturally, anyone that can read a catalog will be informed that several autoloaders are currently “the most reliable!” Actually, the most reliable repeating shotgun is generally the pump, as shell function is removed from the equation.

The notion of “reliability” needs a little amplification, as being able to cycle a lighter load doesn't necessary make a shotgun more reliable, it just means it can cycle a lighter load. Reliability when neglected isn't reliability either. It isn't rational to find that our car isn't reliable because its six year old battery no longer holds a charge.

One way to look at autoloading shotguns actions is simple: it is either gas-operated, or it isn't. If it is gas-operated, there are going to be gas ports somewhere in the barrel to help the ejection process. That is all autoloading shotguns can do, help eject the shells. What operates the shell lifter (a.k.a. elevator or carrier) and closes the bolt is going to be a spring, or combination of springs: springs already compressed by the bolt movement. Nobody wants an unreliable shotgun that I know of, so the truly fussy or problematic autoloaders are no longer made or never were strong sellers. Sadly, some of the best autoloaders ever made are no longer available, either. I'll start by going through a few gas actions.

The most influential gas-operated shotgun came along in 1963, the Remington 1100, a trap model of which is shown above. It was the Remington 1100 that began the gas-operated gun era, long before folks like Beretta figured out how to make a competitive autoloader. Most don't seem to remember that relative newcomer Beretta didn't even make a 20 gauge autoloader until 1971, the A301. The Remington 1100 was good-looking, affordable, and fit most shooters well. While now categorized as a dinosaur, it was anything but in 1963. Most shells fired were 2-3/4 in. lead loads, and while now the poor ability of the 1100 to shoot extreme varieties of loads is part of its downfall, it wasn't that way in 1963. A 12 gauge target load was 1-1/8 oz. at 1200 fps, a field load was 1-1/4 oz. at 1330 fps, and that's all a 12 gauge shotgun needed to function with. The 1100 did that and it did it with no adjustments, unlike the Browning A-5.

Gas-operated

autoloaders need cleaning to either be reliable or to handle pipsqueak

loads. So, as long as you know how to clean a gun, there was little

problem. The number of shells a gas-operated gun can function with

depends on ambient conditions, the type of shells used, and the

individual gun. Some 1100s would go 200 rounds or so, some 300, but it

didn't matter. You followed the manual, cleaned the gun after shooting

it, and most folks don't run more than a case of shells though their

gun in a day, anyway.

The next significant step in the food chain was the Beretta 300 series,

most notably the A303 and Browning B-80 models. Now, you could go 1000

shots before cleaning (like the B-80 owner's manual suggests),

alloy receivers made the guns lighter, and the stocks were

shim-adjustable for height. The idea was to use a 2-3/4 in. barrel for

2-3/4 in. loads, popping on a 3 inch chambered barrel for heavy loads.

A good idea and a simple one, although it didn't take consumers long to

buy 3 inch chambered guns and complain that their 1 ounce reloads

wouldn't cycle.

The Beretta A390 introduced the secondary gas bleed in 1994.

The next step in the cycle was the Beretta 390 (1994), offered with a 3 inch chamber and adding a secondary gas bleed to the front of the 303's barrel housing. Surprising, it was only made, originally, until 1998 or so. Clever folks like Rich Cole made replacement sets of secondary gas springs, a set of five, so now the 390 became the most versatile autoloader ever made, cycling down to 7/8 oz. loads with the stiffest Cole spring and with the lighter spring, could handle the heaviest 3 inch loads without shaking itself to pieces.

Browning took a different tact, using their “Activ valve” in the Browning Gold that was released in 1994 along with the Beretta 390. It was, by far, Browning's most successful gas autoloader introduced until then, and finally offered 1 oz. and up no adjustment load versatility. Apparently worried that people couldn't figure our how to put the secondary gas spring back in the gun, Beretta followed with the harder to clean 391 and Browning extended the Gold into Winchester SX3 and Browning Silver models. The Brownings are easier to clean without any special tools, the Berettas seem to go longer without cleaning, the Brownings are softer shooters, the Berettas have better factory triggers. Browning Golds had speed loading, Beretta's were mostly shim-adjustable, only some Brownings were. Gas operated autoloaders have been reliable, durable, and have cycled a reasonably wide variety of loads ever since the Beretta 390 and the Browning Gold. Reliable if you cleaned them regularly and cleaned them properly, that is. Since then, autoloading shotguns have gotten more expensive, generally uglier, and 3-1/2 inch chambers are there whether you want them or not. The Beretta 391 is no more, the A400 line taking its place, while the Maxus is the flagship Browning gas auto, and the 3-1/2 in. only Remington Versa-Max seems like it is going to be around for a while.

Above, the latest spring thing: the "Kinematic Drive" action from Browning's "A5."

Recoil operated autoloaders were defined by the original, the Browning A-5, that for decades has no competition of any significance. They do require less cleaning, as with no gas system there are no barrel ports to monitor or any gas components to soak and scrub. You also don't have gas blowing out around the barrel, magazine tube, or various exit points. A recoil operated autoloader is essentially a spring gun. Barrel movement from the A-5 moves the breechblock rearward, compressing springs, and the springs do the rest. The Bruno Civolani action uses a split bolt, with a spring in the center. Rearward motion of the gun compresses the spring from rearward, floating bolt body. The bolt spring initiates the rest of the sequence. The Benelli brand group of Beretta has largely had the recoil operated autoloaders to themselves. The Franchi AL-48 is based off of the Browning A-5, the various Benelli's based off the Civolani action, with the Stoeger and Franchi “inertia” marketed guns completing the picture. Browning's new A5, dubbed the "Kinematic action,” seems to owe a great deal to the Civolani action as well.

Gas actions can be soft shooters, as the gas piston that is propelled rearward has mass and also generates recoil, or thrust, but in the opposite direction. Total recoil remains the same, in the end it is zero sum, but gas actions can break up the sharpness. Recoil-operated guns can reduce felt recoil as well, as long as you can adjust the action speed as in an A-5. We don't like adjustments, though, so in the case of the Benelli guns they do what they do. They tend to be lighter than gas guns, so naturally lighter guns kick more. They can't kick more than a fixed breech gun, that isn't a possibility, but lighter guns kick more.

Gas guns don't have to be soft shooters at all: Beretta has proved that. The violent action of the A400 allows cycling with light loads, but between the rapid gas action and the light weight, they can be impressive kickers. It is hardly a coincidence that the “Kick-Off” hydraulic stock is so heavily touted: light guns kick. It shouldn't be a real shocker that the Remington Versa-Max is a soft shooter, it isn't only because it is a gas gun. It is an eight pound gun with a thick recoil pad, so soft shooting is to be expected. One of the softest shooting 12 gauge shotguns that I own is a steel receiver Browning B-80. No recoil pad, just the factory rubber buttplate. It is hardly a soft shooter just because it is a gas gun. It weighs 8 lbs. via Timney trigger gauge. We can't stray all that far from basic gunweight before looking to happy fun time stock gimmicks and so forth. More than a few people has rightly asked, “If these gas guns have so little recoil, then why the wunder-pads, the barrel ports, the pogo-stick stocks?” Good question. Gas operation alone does not eliminate recoil. Gun weight and gun fit can hardly be completely ignored just because an autoloader is gas operated.

As to what action can handle the widest variety of loads, the gas action can . . . somewhat, but only if properly maintained. For most commonly used shotshell loads, fast 1 ounce loads and up, there is no difference worth being obsessed with. One type isn't clearly superior to the other. Based on six million rounds fired per year, Zeke Hayes of Hayes and Hayes outfitters called the Benelli Montefeltros and Beretta 390s the most durable autoloaders, one recoil-operated and one gas, with the Browning Gold next in line. Both recoil and gas actions can be thoroughly competent. Gun fit, weight, handling, aesthetics, trigger quality, and shell handling prowess of an individual model will likely away you in one direction or the other, but not solely based on action type.This discussion quotes excepts from a public document, courtesy of the U.S. Patent Office. It is patent US 7,707,923 B2 of May 4, 2010.

Several types of semi-automatic shotguns are known, the operation of which is based on different principles.

GAS-OPERATED

“A first type of semi-automatic shotgun

is that called “gas-operated”. In such shotgun, the

energy of the gases developed by the powder explosion is exploited. A

small part of such gases is drawn from the barrel through one or more

holes, in order to generate an expansion inside a cylinder closed by a

sliding piston. The piston thrust generates, in turn, an impulse which

recocks the mobile masses, ejects the shell, and loads the new

ammunition.

The piston thrust is extremely variable as a function of the force of the primary impulse generated in the chamber by the powder explosion. Such primary impulse depends on the gram weight of the cartridge which is fired, where “gram weight” means the mass of the charge of fired pellets, therefore the power of the same cartridge. The mass of the powder charge and the mass of the pellets charge are typically proportional.

The gas-operated device, in order to be able to ensure the required reliability, must necessarily be dimensioned for the operation with those cartridges having the lowest gram weight which can be chambered in the shotgun. Once the device has been properly dimensioned, the variability of the cartridges gram weight and the consequent primary impulse translate in a variability of the recocking speed. The minimum speed is the one which is necessary in order to achieve a safe operation of the weapon when a cartridge having a low gram weight is fired. The maximum speed corresponds to the firing of a cartridge having the maximum gram weight which can be chambered in the shotgun.

However, the high recocking speeds translate in high stresses and, consequently, in a decrease of the working life of the shotgun components. In the whole, this results in a short duration of the same shotgun.

In the more modern gas-operated shotguns, it has been successfully attempted to obviate the problem of the high recocking speeds by adopting shutter or self-compensating valves, which are able to exhaust the excess gas associated to the firing of the cartridges having a higher gram weight.

However, such valves, or venting systems, involve an increase of the mechanics and the costs for the shotgun.

Furthermore, the gas-operated systems require a constant maintenance, since the gas which is vented tends to foul unburnt solids, which have to be removed after firing a number of shots.

INERTIAL

Another

type of semi-automatic shotgun is the one called the

“inertial” type. In this type of shotgun, the

compression and the subsequent relief of a spring that is arranged

between the mobile masses and the shotgun frame are exploited. The

spring compression is caused by the shotgun recoil, and it is exploited

in order to confer to the same masses the required recocking speed.

The shotgun with inertial operation is appreciated because it allows limiting the maximum recocking speeds and the resulting reduction of the stresses of the mechanical parts.

Furthermore, the inertial shotgun is characterized by a pronounced constructive simplicity and a reduced maintenance of use. In fact, not requiring any gas drawing, the inertial device does not undergo any “fouling”. Anyway, the standard cleaning is still necessary for the chamber and the barrel, which are contacted by the firing gas.

In contrast, the low recocking speed, which is intrinsic of the inertial shotgun, may be a problem, especially when the shotgun frame has a high mass, and the fired cartridge has a low or very low gram weight. The low recocking speed translates in a low shell ejection promptness and a high risk of jamming.

Furthermore, the operation of such type of shotgun is highly affected by the user's behavior, particularly by the type of reaction which the user opposes with his/her shoulder to the shotgun stock.”

Though this patent apparently was used to cover the now introduced and

discontinued Beretta UGB 25 and is by Ugo Beretta, it does cover

self-loading shotguns in a far more frank, less flattering manner than

most ad-copy.

The excessive bolt speed and associated wear is a potential issue. When seeking the “shoots everything” gas autoloader, the 12 gauge that we might brag handles our wimpy 3/4 oz. reloads is a poor choice for a steady diet of higher intensity loads, with resultant high stress and comparatively short life.

While this discussion is not particularly flattering to gas autoloaders, it also frankly describes the problems of inertial guns, whether a heavy gun, light loads, a combination of both, and as mentioned function is affected by how the individual mounts the gun. In a solid fixture where rearward movement of the gun is eliminated, the inertial action will not function.

While Beretta describes the maintenance of the gas gun as “constant,” that isn't strictly true. Regular cleaning is required, but the intervals vary from model to model and the most important potential benefit of gas operation, softer and more comfortable shooting, is ignored.

The inertial action, along with its predecessors, the long recoil action (Browning Automatic Five) and various short-recoil actions (Double Auto, A500) does shoot cleaner, and requires less maintenance. The inertial action is cheap to make. Whether they are marketed cheaply or not is another matter, but there are comparatively few parts to machine and assemble. The inertial action can be generally a lighter action as well with out much difficulty, due to the complete lack of gas pistons, seals, piston shrouds, action rails, extra valving, etc.

While Beretta sure doesn't seem enthused about either gas or inertial actions, things are not as dire as their comments suggest. The most influential gas gun, the Remington 1100 of 1963, showed off the soft-shooting potential of gas shotguns by virtue of its 8 lb. weight and its gas system. Though a crude gas system by some standards, it improved on its predecessor (the “Dial-A-Matic,” gas regulating cap Model 58) by eliminating load adjustment by the user. It still needs 300 shot or so cleaning, but it popularized the gas shotgun like no other. Note that the "Dial-A-Matic" sometimes called "dial a duck" compensated only for 2-3/4 inch shell variations, like the standard Browning A-5.

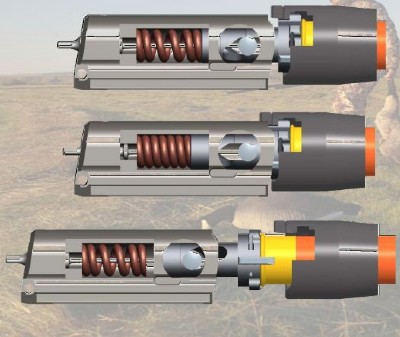

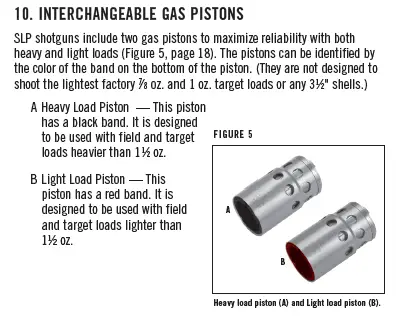

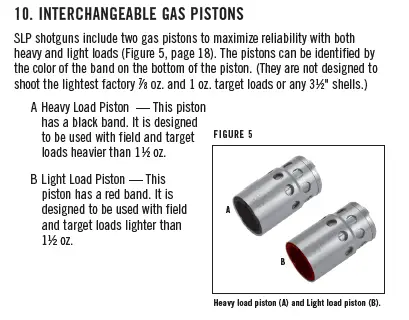

The system used by the Beretta 302 / 303, Browning B-80, and Browning B2000 of changing the barrel as needed from 2-3/4 in. to 3 inch chambering took care of the excessive ejection distances and bolt speed. It was and is a very good system, but changing barrels has lost its appeal. The 1993 Browning Gold (Activ Valve) platform was simplified and improved in 1999 with the Winchester SX-2 that now is the Browning Silver (in 12 gauge). This platform is also the FN SLP; two Active valve pistons are supplied with the SLP and some SX2 Models.

Most folks know whether they are going target shooting or turkey hunting, so getting your bolt speed down to a 4 – 6 foot ejection distance is a good idea to reduce stress, vibration, and get the most out of your gas gun. You have that option with a Beretta 390 or 391 with a secondary gas bleed spring set from Cole Gunsmithing, piston switching with the Gold / Silver / SX2 / SX3 / SLP platform, and the Weatherby SA-08 gives you a pair of pistons with each shotgun for just that purpose. That, and a new mainspring every 10000 rounds will help you get the most out of your gas gun, even if it not strictly needed.

IN 2020

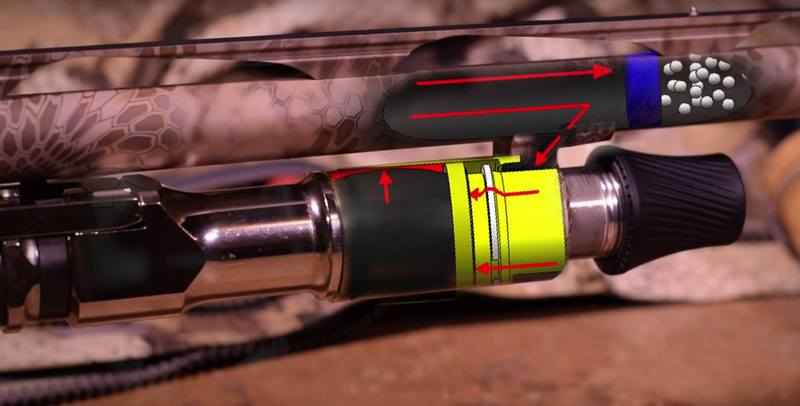

Both the complaints about gas autoloaders and the complaints about inertia guns (made by Beretta) have been addressed, albeit in different ways, but not by Beretta. The Fabarm "Pulse Piston," used in XLR5 and L4S hunting models, eliminates Beretta's own complaints about" shutter or self-compensating valves."

There is no such valving in the Fabarm Pulse Piston, as the piston itself becomes a friction brake that works in concert with additional gas, as shown above. Not only does the Pulse Piston prevent over-driving the action with heavy loads, it serves as a wiper to keep the inside of the barrel shroud clean. It is a simpler and lighter gas array than most, which allows the L4S to be a 6-3/4 lb. 12 gauge gas autoloader.

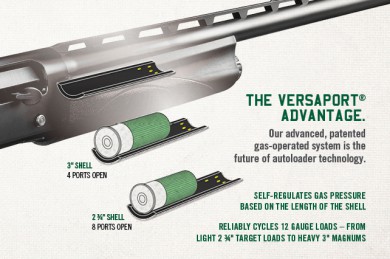

The Remington Versa-port system, depicted above in the V3, cleverly uses the unfolded shell length itself to meter the amount of gas flowing into the system. It, too, simplifies the action, needing no additional valving when equipped with exhaust tubes as in the V3 walnut model.

The Retay Masai Mara eliminates the Beretta complaint about the "low recocking speed, which is intrinsic of the inertial shotgun, may be a problem." Sometimes called the Benelli Click, the patented Retay Inertia Plus Action (standard in all Retay USA models) eliminates the failure of the bolt to go back into battery by the addition of a simple, effective torsion spring.

Copyright 2011, 2013, 2020 by Randy Wakeman. All Rights Reserved.