A Dive into Bismuth Shot

The invention, discontinuation, and re-invention of bismuth shotshell loads has been going on for decades. Legendary professional ballistician Ed Lowry covered bismuth extensively in 1993, recognizing the ballistic potential of bismuth compared to steel.

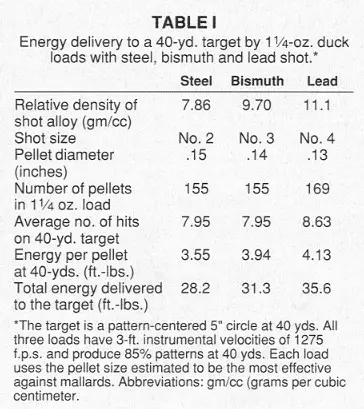

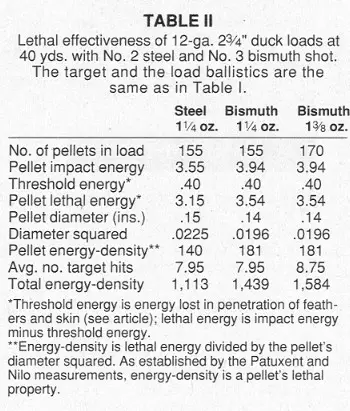

When it comes to shot performance, density of the shot material is the most important factor. Bismuth is best described as a halfway point between steel and lead. Lowry referenced Seyfried's work with bismuth, yielding patterning efficiencies as dense as 92% at 40 yards with buffered bismuth loads. Ed Lowry mentioned that if duck hunters found #4 lead as the best diameter, #2 steel as the best shot size (for steel), it follows that #3 bismuth is the best shot size for bismuth. The full Lowry examination is here: https://www.randywakeman.com/LowryBismuthShot1993.pdf .

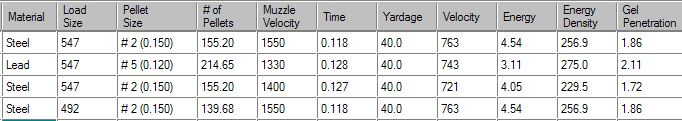

Note that 1330 fps

lead #5 is loudly superior to 1550 fps steel #2 at all

ranges.

Of late, several companies have joined the bismuth bandwagon, along with the usual bombastic claims that “their bismuth” is something special and has mystical properties other than what bismuth is. Bismuth is not as good as lead and cannot be, as it is limited by density. It seems that some ammo companies have forgotten that buffering largely solved the brittleness and fracturing problem with bismuth. Winchester has a “Shot-Lok” bismuth load, a 3 inch 12 gauge with 1-5/8 oz. of #5 bismuth at 1200 fps. It is the wrong pellet size and too heavy of a payload to be practical for duck hunting, however. Hevi-Shot, perhaps the world's most dishonest shotshell company, ignores #3 bismuth as well. Kent bismuth has had severe fracturing problems to the point where most of the shot fractures and never leaves the wad.

That leaves BOSS shotshells, from self-described “Michigan basement-ballistics prodigy Brandon Cerecke.” Brandon is the president of Ultra-Seal in Bridgman, Michigan, and has formed DLM Holding Group LLC of Bridgman to market BOSS shotshells. In May, 2019, DLM Holding filed for a WIPO patent, a method for copper-plating bismuth loads. Although the patent contains some fanciful wishful thinking claims about penetration and stories of killing geese at 10 – 88 yards with a #3 / #5 bismuth mix, more believable claims are 77% patterns at 40 yards with a factory Benelli full choke. Whether this is one pattern or an average of 10 patterns is not mentioned. While this does not favorably compare with the 92% Seyfried load, or the 85% loads used by Ed Lowry, it is a significant improvement over standard bismuth loads.

Brandon's copper-plated bismuth shot seems to have largely eliminated the need for buffering, and has mitigated the fracturing problem present in most other bismuth loads. Best of all, Boss bismuth loads are affordable compared to tungsten based loads.

If you don't mind a heavier payload, you can go with the Boss 12 GA 3” MAG 1-1/2 oz. #3, 1350 fps at $31 / 20 shells or $280 for 200 shells. For shorter ranges, less cost, and less recoil, use BOSS 12 GA 2-3/4” MAG 1-1/4 oz. #4 at $29 for 20 shells, $255 for 200 shells.

Bismuth, aside from the cost per shot advantage over tungsten, is safe for lead only barrels and chokes. See https://bossshotshells.com/ to get your BOSS loads on order, before the seasons hit.