On Savage Breechplug Care

My other two used breechplugs have over 750 shots each through them, and they also exhibit no evidence of erosion.

Face erosion has NOTHING to do with breechplug strength. A breechplug is simply a threaded fastener; a threaded fastener with a hole in it. NO BREECHPLUG IS DESIGNED TO SEAL AT THE FACE. If they were, you wouldn't have to lube your breechplug at all. It is the pitch diameter of the thread engagement area that retains the breechplug; the threads take the rearward thrust-- the breechplug face is designed to seal or retain nothing.

You would think by now, that the some baseless claims that every Savage breech plug erodes inside 500 shots would have been become evident over these last six years. Experienced shooters such as Mark Anthony, J. J. Smithey, Darrell Wallace, Tom Drechsler, have all written in to say they have seen no wear on their 10ML-II breechplugs to date. If you want to inhibit the possibility of premature breechplug erosion, just keep your breechplug tight. It also tends to keep your groups tight as well. Bill Ball and Henry Ball both have breechplugs with many, many more times the number of shots through them than mine-- no wear. Intentionally shooting the 10ML-II with the breechplug loose is the only way they were able to get them to erode. Just replace it, that's all.

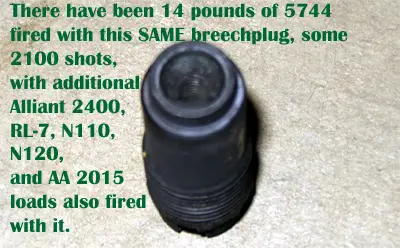

ALL breechplugs will eventually erode. The only breechplug that has had noticeable erosion for me, personally, is a Thompson Encore plug after 1000 shots or so. It was ugly at the nose, and that's why I threw it out and screwed in a new one. They are replaceable, and designed to be replaced. Most hunters just don't shoot enough to see erosion. Few muzzleloaders fire more than 10 shots a year. The breechplug depicted above would be a nifty "210 year supply" for most hunters.

Savage 10ML-II breechplugs can be intentionally eroded fairly quickly, and have been in extended testing. If you want to erode a breechplug, just shoot your gun with the breechplug loose. Naturally, non-recommend propellants such as Hodgdon Lil' Gun erode things quickly. Erosion is old news, ask anyone who shoots a .220 Swift what the accuracy life of their barrel is.

The 10ML-II breechplug is designed to be screwed down snugly. Upon ignition, the primer puffs out-- and engages the breechplug in a slight press fit. That is why the Savage 10ML-II has the least blowback of any muzzleloader made, and the bolt is not designed to be disassembled for cleaning-- because you don't have to.

The primer cannot stick in the breechplug; it is attached to the bolt. However, when you open the bolt with a very clean, well lubed breechplug, you can inadvertently unscrew the breechplug in concert with the throw of the bolt. I've done it myself, with a new plug. It is a good idea to check breechplug tightness after the first five shots or so.

An inherent safety feature of the Savage is that the gun cannot be fired with the breechplug significantly out of battery. If the breechplug backs out more than a small amount, the bolt will not close. This is not the case with several plunger type actions.

The unthreaded snout naturally does not hold the breech plug in place-- the threads do. It is no safety issue. Cutting more internal threads weakens a barrel, and of course does not strengthen it.

If you go to Thompson's website, they brag about the unthreaded portion of their breechplug: "Removable Universal Breech Plug The Encore 209x50 Magnum features a stainless steel universal breech plug which is easy to remove. This universal breech plug allows for quick reliable ignition with both loose powder or Pyrodex® Pellets. It’s special shoulder sealing design prevents fouling from making its way into the threads . . .

That's one of the reasons WHY the Savage has an unthreaded portion-- to protect the threads. The flanged part provides a positive stop to locate the breechplug with precision. Not necessary in plunger guns, for example-- it is indicated in a bolt action like the Savage as you have approx. a .035" firing pin throw, and need something like .010" indentation of a 209 shotshell primer for positive ignition.

The unthreaded portion was on the original 10ML as well-- identical length. The only reason Henry's prototypes lacked an unthreaded portion is because he was hand making his breech plugs on an engine lathe-- and couldn't easily stop the threading.

Here's a look at a Thompson "Black Diamond" breechplug. Not near the thread engagement area of the Savage-- and, it too has a unthreaded portion at the front to protect the comparatively small number of threads it has. The pitch engagement area is what controls the strength of the threads, along with the strength of the parent metal itself. 4140 Chrome moly, and heat-treated AISI 41L40 as used in the Savage is generally stronger than stainless steel. That is of course why stainless barrels are generally of a thicker wall than 4140 Chrome moly in small arms applications.

It is no safety issue at all in the Savage. Nothing is with a gun that has a built-in 250% safety factor designed in (when used with recommended loads). It can be, however, an accuracy issue-- if your breech plug is shot in unsnugged condition for a time, your accuracy will likely erode as well. So, to summarize, just make sure that your breechplug is properly tightened down for longest life. In any case, if your breechplug looks a bit ugly, just replace it. As mentioned, it is designed to be replaced, it is a wearing part, and a worn breechplug should be replaced in ANY muzzleloader.

Postscript:

It is the consensus of muzzleloading firearms manufacturers and engineers that gas cutting, a simple byproduct of powder ignition, CAN found to some extent in all muzzleloaders that have breech plugs, if they are fired enough. Face breechplug erosion is of no safety concern, as the threads of any breechplug provide the strength. However, breechplugs are a wearing part designed to be replaced when significant wear occurs as part of normal good maintenance, and to ensure peak performance. This is true regardless of brand of muzzleloader, regardless of propellant. It is also true where the normal wear exhibits itself as corrosion from sulfur-based or sugar-based propellants, or normal wear found from the firing cycle. As muzzleloading legend Dr. Gary B. "Doc" White mentioned to me long ago, "Heck, ALL breechplugs erode. It is just that most muzzleloading hunters don't shoot enough to ever experience it."

Email: randymagic@aol.com

© 2005 by Randy Wakeman

Custom Search

Custom Search