Winchester Long Beard XR: The Best Lead Loads Ever Tested

Buffered shotshell

loads have been around for some time. Tom Roster has a booklet on buffered

reloads: “Tom Roster's Buffered Lead & Bismuth Shotshell Reloading

Manual.” In the area of factory buffered shotshells, perhaps

the best known is the Winchester Grex-buffered Lubaloy Super-X loads used

in Nilo Farms testing.

The findings published by Winchester's head of ballistics, Herman Bockstruck, showed that waterfowl crippling was a bigger factor with steel than the alleged problems and sometimes mythical problems with lead. One of the later complaints about the Nilo Farms testing was that the Grex buffered loads were too good and that most hunters settle for the cheapest stuff that goes bang, rather than the best performing shells.

Grex and other buffered loads (PSB) have been improving shotshell performance past the 95% 40 yard efficiency level for many years. It is a costly process to use, for often the buffer is applied to the top of the shot and settled into the column by the use of vibratory tables. For handloads, often you drop a dip of the material to the top of the shot column, tap the hull until it settles, and then use an over-shot card to try to keep the stuff from leaking out. Commercial loads have used varnish-type sealants over the crimp area.

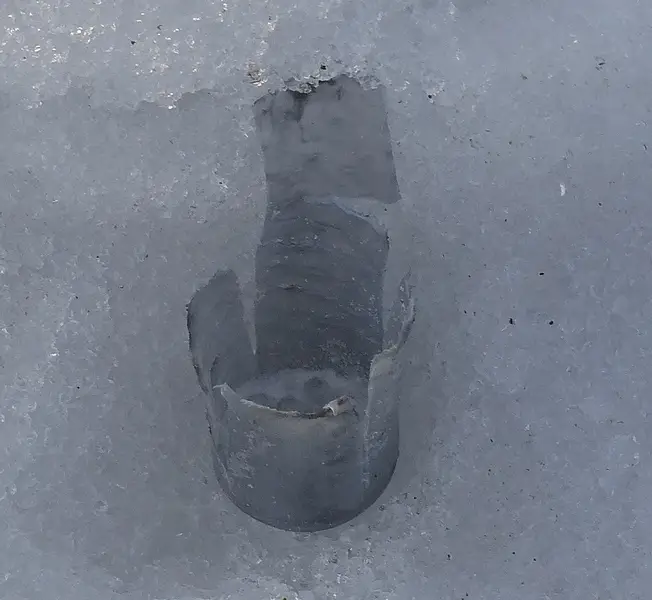

No such leakage issues are apparent in the Long Beard loads. As a matter of fact, the wad itself retains a small amount of the liquid-when-applied buffer, and travels about 35 yards. An example that landed in the wet snow is shown above.

The Winchester Long Beard XR loads use a clear plastic applied to the shot column, that doesn't just fill most of the voids, it fills all of them. The completed shell has a temporally solid shot column that essentially eliminated shot deformation at the time of exit from the muzzle. Upon ignition, the solid shot mass becomes a shot column of essentially 100% loading density, but the clear plastic resin fractures and turns to dust. To say that the new Winchester XR loads (now in Long Beard turkey loads with Rooster XR pheasant loads to follow later in 2014) work well is an understatement.

About the only "bad" thing there is too say about these new XR Winchester loads is that there is no immediate love for 20 gauge fans (like me). This new buffering idea should work wonders in three inch 20 gauge hunting loads, but I'm told it will likely be 2016 before anything might be available in the 20 gauge. Although I patterned the Winchester Long Beard loads until I ran out of shells with several shotguns, the short video above is with an Ithaca Model 37 Turkeyslayer and a George Trulock Precision Hunter choke: .730 bore in the Ithaca, .660 exit diameter on the Trulock Precision Hunter, for a constriction of .070 inch.

In general, the standard Trulock recommendations for lead shell turkey chokes are a pretty safe bet. Here are a few of them:

Beretta and Benelli

Mobil style- PHBER12660

Beretta Optima Plus-PHOP12668

Benelli Crio Plus-PHCRP12660

Browning Invector-PHWIN12665

Browning Invector Plus-PHIP12670

Remington Rem Choke-PHREM12665

Winchester Win Choke- PHWIN12665

In a Trulock Precision Hunter Choke, 65 - 70 thousandths of an inch actual constriction is going to get you satisfying turkey patterns.

Winchester deserves a round of applause for a new standard of performance in lead shotshell loads. Perhaps the best news of all for active hunters is their affordability. The true high-density loads are expensive, due to the high cost of tungsten. That situation is highly unlikely to change. Unlike the $4 - $5 per shot tungsten loads, the Long Beard shells run about twenty dollars for a box of 10 shells, or right at $2 for the 3 inch Longbeard XR shell. This product is going to be a runaway smash hit, so you better get yours while you can.

Copyright 2014 by Randy Wakeman. All Rights Reserved.

Custom Search