Using a Shotgun to Drop a Bird, Part Two

A pond full of non-migrating, resident Canadian geese . . . a very familar sight in northern Illinois. Photo by Randy Wakeman.

Part of the confusion (or frustration) with wingshooting is that most of us humans find comfort in precise, black & white answers and clearly defined rules. Shotguns offer none of that. What is marked on choke tube means nothing, specifically, and even performance levels vary. A “70%” pattern may well be a 64% pattern on one shot and 76% on the next one. Though is takes only one pellet to cleanly take a bird, it takes a lot of pellets to insure that one pellet vital hit happens, and the normal distribution of a pattern means that often we will have four or five quickly lethal hits to get to the 95% - 97% level of one shot drops.

We all tend to put more emphasis on personal experience than is rational. Way more. Even some of the worst performing choke and loads can manage to kill a bird; that hardly vindicates their use. Some of the problem is relying on false information, information just assumed to be accurate. We assume that the shot diameter in the shell is what is stamped on the box. We assume the velocity is as advertised. We assume that downrange ballistics are precise; but they cannot be.

A ballistic coefficient, the ability of a projectile to withstand velocity decay, is never precise. It varies widely by ambient conditions. It varies continuously by velocity. Based on temperature, humidity, and altitude a ballistic coefficient can vary by 30% or more. The folks at Sierra have good information on this online. It also doesn't help that published shotshell pellet exterior ballistics have always been deeply flawed. Despite being funded by SAAMI in 1969 to correct them and being corrected by Ed Lowry in 1970, they have not been widely disseminated to this day.

Further testing motivated by the mandate of steel shot (actually soft iron) against lead revealed both good and bad. Steel wasn't quite as bad as originally thought, due to its superior, perfectly spherical form. Unbuffered lead was discovered to be far worse than buffered lead loads, as buffered lead had both the density advantage of its parent material and the form factor advantage of retaining sphericity. Penetration testing into gelatin came from the Army Medical Corps. This has been advanced significantly from the early testing by Dr. Martin Fackler and others. In July, 1989, the FBI discussion of wounding factors concluded in part, “Kinetic energy does not wound. Temporary cavity does not wound. The much discussed “shock” of bullet impact is a fable and “knock down” power is a myth. The critical element is penetration.” All of this is consistent with the function of spherical or blunt projectiles and also consistent with what Arthur Dzimian discovered in 1958 with steel spheres. For strike velocities under 1000 fps, penetration is essentially proportional to velocity.

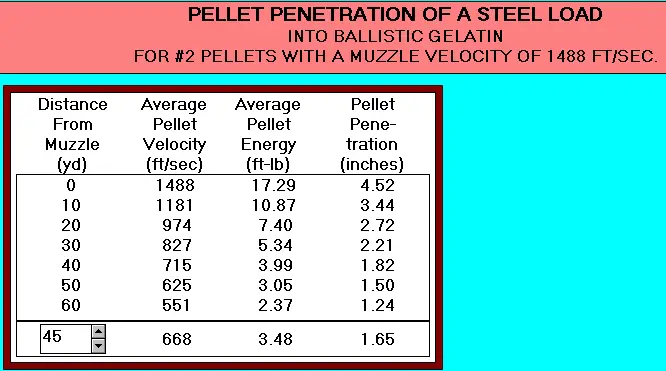

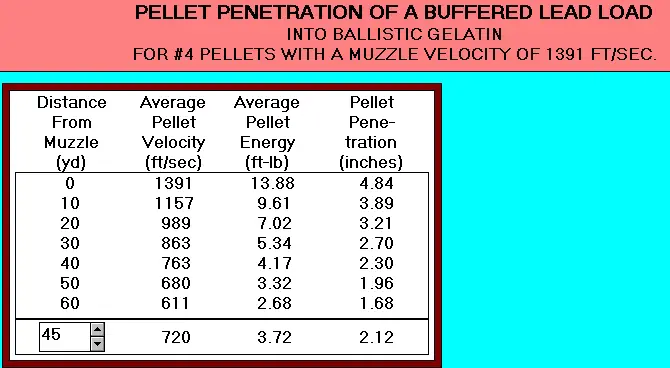

By the time “Shotshell Ballistics for Windows” was released (1996), Ed Lowry was well aware of the needed adjustments to the antiquated SAAMI tables and was able to give very usable comparisons between lead and steel. A direct comparison of #2 steel at 1400 fps 3 foot velocity and #4 lead at 1330 fps 3 foot velocity follows, as per Ed Lowry, both with "modified" chokes. Despite the higher launch velocity of the #2 steel (1488 fps) vs. the slower #4 lead (1391 fps), the lead load offers more penetration at all ranges. The lesser density of steel is what limits it. This should also, yet again, point up the fallacy of thinking energy is a barometer for lethality. Even though the steel load has more energy than the lead load at 0, 10, and 20 yards . . . it still yields less penetration. Despite the higher muzzle velocity of the #2 steel load, it already has less strike velocity than the #4 lead load at just 20 yards.

Unfortunately, shotshell companies and hunters often have different interests. Hunting is expensive enough, so the consumer often opts for the cheapest thing that goes bang. Yet, lead performance has not just been met, it has been exceeded by spherical high density shot. With the high price of raw materials involved (tungsten), the higher performance shotshells are not often used except for turkey. Anything that deviates from perfectly spherical necessarily patterns more openly, has a lower ballistic coefficient and lower strike velocity. That means that deformed shot, whether "Blind Side" or something else is a negative, unless you are looking for a spreader load. Facts don't always get in the way of an aggressive marketing campaign, though, so some of it gets purchased.

Even with non-deformed, spherical steel, the ballistic coefficient is so very poor that muzzle velocity increases net you more recoil, but very little increased performance. The Hobson's choice of larger diameter in steel means a correspondingly larger body of atmosphere to push through, largely negating the hoped-for gain. The more aggressive hyper-velocity steel loads offer the worst of everything: high recoil, lighter payloads meaning lower pellet counts, and more open patterns.

So, today's shotgunner has options. Buffered lead is as good (or better) as ever, but for so-called "no-tox" use it is a matter of "biting the pellet," ponying up for Kent Tungsten Matrix, Nice Shot, or Tungsten-High Density spherical loads. The second option is simply restricting range if using the "Rule of Two" with steel, or closing the gap a bit with going three sizes larger than lead, paying close attention to patterning and choking for the ranges anticipated, as needed, to compensate for the lower pellet count.

Copyright 2012 by Randy Wakeman. All Rights Reserved.

Custom Search