The Questionable Record of Steel Shot

Above, Federal's "Anatomy of a Shotshell." The result of use of steel shot (99% iron) has reduced or elminated the usefulness of amaller gauges and compression-formed hulls due to case capacity considerations. The 12 gauge shells that were mostly full of air and stacks of wadding in times past are now at or near case capacity.

The debate over steel shot has been going on for years. Some of the information is conflicting. "The average waterfowl hunter cannot break six of eight clay targets at 20 yards,” says Tom Roster. Yet, a CONSEP study showed the average first shot taken on a goose was 67 yards. In the same study, the average shot on a duck was 53 yards.

Tom Roster objected that the NILO farms study, that illuminated just how poor steel was, was unfair to steel, as the lead loads used were too good: high-antimony, buffered Winchester-Western loads that were the “Cadillac of Lead loads,” and used by just five percent of waterfowl hunters back in the day. Later in the same paper, Mr. Roster claims buffered loads are used by 10% of hunters, however.

Ed Lowry agreed, in part, finding that steel shot retains a minimum of 12% higher form factor than steel, and redid all the SAAMI ballistic tables as well that were completed back on February 26, 1970, to the benefit of steel. Tom Roster complained, in 1978, about the poor 1100 fps early steel loads, though 1365 fps steel loads were already available. Mr. Roster goes on to suggest that steel loads, two shot sizes larger than lead, could be as capable at bagging waterfowl to 70 yards.

Mr. Roster also dramatically misrepresented the pattern efficiency of steel, claiming that while lead struggles to get to 70% pattern efficiency, steel “typically patterns 82 – 90 percent at 40 yards” and 45 – 60% at 60 yards. This is a very long ways from fact, however, as even today (2013) with a factory “modified choke” called “full” when used with steel, 70 – 75 % patterns are typical. The 82% - 90% pattern is not typical at all. As evidence of something, hard to discern what, Roster talks of 1300 fps experimental 1-1/4 oz. #1 steel loads used for six consecutive one shot kills on geese, with nine shots. That would seem to quite be a math problem.

But, Ed Lowry and others loudly disagreed with Mr. Roster. Ed Lowry wrote, in 1989, “There are some very able shotshell development engineers in the industry. But steel's density limitation is such that that no one of them will ever be able to to develop an effective long range steel waterfowl load.”

Ed Lowry's research showed Roster's notion of shot string to be well off the mark, with steel loads producing pattern thinning actually worse than lead. Few folks have agreed on much of anything, and the many of the “studies” performed over the years aren't scientific studies at all, but just poor collections of interviews. A review of many of them shows pseudo-scientific babble terms like “more effective” and less effective, better and worse patterns, more lethality and less lethality, without any definition of what better or worse means, much less how much better or worse.

Mr. Roster claimed that “energy” was a factor, you need 3 fpe to kill a goose. The wrong-headed notions of energy and energy transfer have long ago been disproved by Dr. Martin Fackler and others. Yet, some still cling to kinetic energy as being a wounding mechanism, though it is transparently obvious that it is not. It is as if someone thinks that arrows don't work, yet they've taken everything on the planet including bull elephant despite their spectacular lack of kinetic energy.

A 1400 fps 3 ft. instrumental velocity load of #2 steel has 3.05 fpe per pellet at 50 yards, according to Winchester Research. A 1330 fps load of #5 lead has 2.39 fpe per pellet at 50 yards. Those that blindly buy into the energy myth would have to say that #2 steel is far superior to #5 lead. Of course, the opposite is more true, for at 50 yards #5 lead creates 1.65 inches of penetration into ballistic gelatin, while faster muzzle velocity, higher energy steel actually has less penetration, 1.5 inches.

Steel shot itself, is mostly iron. Daisy Manufacturing uses low carbon steel 1008 wire to make its shot. Steel wire of a selected diameter is protruded through a hole in a header machine plate. A blade cuts the wire to the desired size. Opposing dies catch the falling piece and press it into a ball. The collected balls are ground using cast iron grinding wheels to a specified diameter. The shot is then annealed to a maximum hardness of79 on the Rockwell 15T scale. The final step is the application an oil coating to prevent rust. There is no polishing. Daisy manufactures steel shot in whole number sizes from #8 to F (TIT) size (14,15). 1008 steel wire is 99% iron.

Though there are few areas of agreement, there is one: steel, while deficient in density by having only 70% of the density of lead, the clear advantage of steel is its ability to retain spherical form factor. However, due to marketing-driven misguidance, the one advantage universally accepted that steel has, the ability to retain its sphericity, is gone with Black Cloud and even worse, Winchester Blindside. As Winchester Blindside has no sphericity to start with, it isn't possible to retain it.

The standard performance designations of choke do not change regardless of shell or shot type. If you throw a 65% pattern into a 30 inch circle at 40 yards, that is full choke performance regardless. The obvious problem revealed with a comparison of #2 steel to #5 lead, aside from the weaker penetration of steel, is pellet count. One and a quarter ounce of #2 steel approximates 156 pellets. One and a quarter ounce of 3% antimony #5 lead approximates 212 pellets. The 65% #2 steel load is about 101 pellets, while a 65% lead #5 load is about 138 pellets. With a better than 36% pellet count deficit, steel “full” choke loads have a lot of ground to make up.

As a practical matter, they don't get there. A 1-7/8 oz. buffered lead load of #5 shot is about 319 pellets. Not my idea of a comfortable load to use, but they have been readily available for a very long time. Now, a 65% pattern is 207 pellets or so, more than 32% more than the 1-1/4 oz. steel load has before it is even fired.

Ed Lowry later discussed (September, 1993) what was learned from the two extensive mortality studies at Patuxent and Nilo Farms: “Both programs also disclosed that if two pellets deposited the same amount of lethal energy, the smaller one's energy is more lethally effective.” Lowry continues, explaining that “the much touted theory of No. 2s “compensating” for steel's low density, and thereby matching lead No. 4s, is rudely rejected by an elementary law of ballistic behavior.” Lowry also mentioned, “Steel's density cannot be increased, its pellets cannot be made rounder, and its scouring hardness cannot be made much softer. This tells us that steel shot is now as good as it will ever be. Thus, the doctrine that steel is ballistically equivalent to lead is emphatically contradicted by the laws of physics and the measurements at Nilo.”

A further complication is what shotguns themselves are designed for presently. The CIP has three standards of steel shot proof. Standard 12-65 to 12-70, 740 400, (1310), High Performance 12-70 (1410), and High Performance 12-73 and longer.

The highest standard is “High Performance Steel for 12 Bores, 12-73 and Longer.”

“Where the steel shot diameter exceeds 4 mm (“BB” or larger), only weapons having barrels with a choke less than 0.5 mm (equivalent to half choke) are to be used. The mean velocity measured at a point 2.50 m from the muzzle, for any 12/70 or longer cartridge, must be = 430 m/s (around 1,410 ft/s).”

A 1250 fps #2 (spherical)steel load has 588 fps strike velocity at 50 yards. A 1400 fps #2 steel load has 625 fps strike velocity at 50 yards. Go to 1500 fps, you have 649 fps strike velocity at 50 yards. Any deformed, non spherical version of steel shot sheds velocity even more rapidly, offering lower strike velocities. While it wouldn't be correct to suggest higher muzzle velocity does nothing, but it doesn't offer any significant return for the added recoil.

It offers even less in actuality, considering SAAMI muzzle velocities specifications are +/- 90 fps, the lab velocities are not recorded with your hunting atmosphere or temperature, and stated velocities are with 30 inch barrels in 12 gauge . . . which you may or may not be using.

WHY EVERYONE HAS IT WRONG

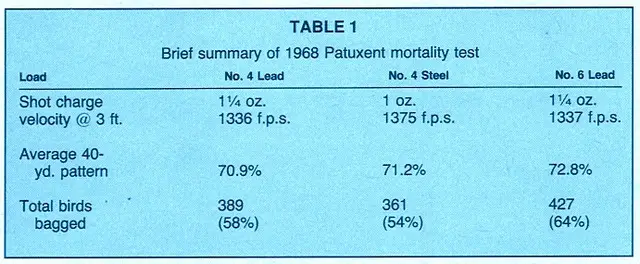

Overall crippling and lost bird rates were 42%, 46%, and 36% at Patuxent, designated as unbagged birds. This is despite using game farm mallards restricted to firing harnesses and perfectly centered electronically triggered shotgun live fire. This level of very poor results should give everyone pause, regardless if you are inclined to favor lead or steel. Neither shot type performed at a high level of effectiveness at long range.

Most every study ever done conflicts violently with other studies. If they don't have it all wrong, they sure don't have it all completely right. There are clear reasons for this. Between the Patuxent and Nilo studies, some 4400 game farm mallards were killed in flying harnesses, with shotguns fired electronically to precisely center the pattern.

But that isn't how ducks (or anything else) are hunted. No one shoots at birds in flying harnesses and it isn't possible that the harnesses themselves perfectly simulate free-flight. Nor do human beings fire shotguns by remote electronic triggering, not all patterns are perfectly centered, and hunting isn't shooting at a bird at one exact, precisely known range. We also hunt wild animals, not pen-raised or game farm anything.

Mr. Roster's lament that buffered lead loads are too good is a silly one. Whether and individual patterns his gun with a wide variety of shells until he finds the most appropriate shell / choke combination for the application is totally the individual's choice. Certainly, those that take the time and effort to find the best-performing loads have a field advantage, just as those that practice more and are better wingshots do as opposed to those that are not. Who patterns and who does not, who is a better shot and who is not, all of these components are matters of sheer, baseless speculation. Who shoots only within their effect range and who skybusts? No one knows, it isn't worth the idle gossip, for we can only control what we do, not what someone in another state or country theoretically may or may not do.

Buffered high-antimony lead loads are substantially superior to softer, unbuffered loads. Whether five or ten percent of hunters use them or not is not relevant. What is relevant is that they are better-performing loads. Whether people want to use better performing loads or not is only their decision.

The same scenario is true of steel loads, where use of lead is not an option. Of course they work, within range. Higher density shot materials, from Tungsten-Matrix to Nice Shot to Winchester HD to Federal Heavyweight, along with other tungsten loads are vastly superior to steel beyond any doubt. No one I know claims to be a subsistence hunter; hunting is a recreational activity. The cost per pound of wild game meat makes no strict economic sense. It may make a bit more sense to some than shooting at things we never eat, like paper and clay, but it if it is just food we want, perhaps we should all raise chickens and buy a goat.

The important part is what tools we have available to use, currently, to allow us to become more effective hunters in the field. Shotshell and choke selection are two of the most significant tools that we have.

Copyright 2013 by Randy Wakeman. All Rights Reserved.

Custom Search