The 3-1/2 inch Twelve Gauge: Pro and Con

The 3-1/2 inch unfolded length twelve gauge has been with us for some time by now, having been introduced in 1988 by Mossberg in the Ulti-Mag. Now, over 25 years later, you might think that there would be some general consensus as to its value, but that isn't the case.

The 3-1/2 inch 12 gauge has a higher allowable maximum average pressure (MAP) according to the SAAMI specification at 14,000 PSI versus the 11,500 PSI of other twelve gauge shells. Whether factory shells are actually loaded to that is an unknown, for most ammunition companies don't make that information available. The general idea of the 3-1/2 inch shell is an attempt to help out poor-performing steel loads compared to their lead counterparts. That, it fails to do, for low-density shot can only be low-density shot.

It does offer increased

payloads, though, as 1-1/4 oz. is a common 3 inch steel load and 1-1/2

oz. is a common 3-1/2 inch steel load. Along with increased payloads,

you naturally get increased recoil and another negative is that they tend

to be obnoxiously loud, a good technique for destroying your hearing and

annoying your buddies.

Shotgun manufacturers tend to like 3-1/2 chambered guns, for they can

sell you a gun that costs no more to make for more dollars. Is there any

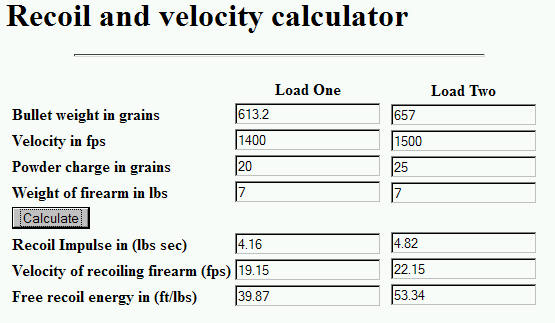

advantage? Well, comparing 1400 fps 1-1/4 oz. loads to 1500 fps 1-1/2

oz. steel loads, there is. As is always the case, it varies by individual

gun, choke, and shell, but you can get roughly the same pattern percentages

with 3-1/2 inch shells as you can with 3 inch steel shells.

The notion that the 1-1/2 oz. payload of the 3-1/2 inch shell is something wondrous does not bear any scrutiny, for 1-1/2 oz. 2-3/4 inch 12 gauge shells aren't unusual, and my favorite turkey load is 1-1/2 ounces out of a 20 gauge, albeit at modest velocity.

Recoil of a representative 3 inch steel shell (Load One) vs. a common 3.5 inch steel shotshell.

The negatives include unwanted noise, unwanted recoil, and unwanted sticker price on the gun. The 3-1/2 inch steel ammo is a bit more expensive as well. Flipside, it does give you more payload in a steel application and can be a marginally better long range load . . . in the neighborhood of five yards or so.

Not so with most lead

loads, where 3-1/2 shells pattern more poorly than than 3 inch shells

for the most part.

The rest comes down to the individual gun. For inertia guns, you lose

reliability on the extreme low end of things, although I personally hunt

with nothing lighter than 1 oz. loads in anything: 12, 16, or 20 gauge.

In several tests, 3-1/2 inch Maxus, Super Vinci, and A400 3-1/2 in. guns

all handled factory 1 oz. loads for me without issues.

The 3-1/2 autoloader also makes sense when that's the only way it is offered, as in the Versa Max. The Versa Max action does nothing to compensate for 2-3/4 inch shells, but it does automatically block off three its seven ports when using 3 inch unfolded shells, and is the softest shooting 12 gauge, when shooting 3 inch shells, on the market due to three factors: the automatic port block off, its substantial eight pound weight, and its extremely thick recoil pad.

So, there are valid reasons why a 3-1/2 12 gauge makes some sense, but very few, and only with very comparatively very few autoloading shotguns. The performance-minded individual will avoid steel altogether, for there is no 3-1/2 inch shell that compares with Tungsten Matrix and other higher density shot materials.

Copyright 2014 by Randy Wakeman. All Rights Reserved.

Custom Search