Still Can't Figure Out that Browning A-5?

Maybe this will help. Many "problems" associated with that old A-5 aren't problems at all. It is just a matter of setting up the friction rings properly. Most A-5s I've obtained over the years aren't set properly, in the case of a few A-5 Mags . . . they can't be, as the parts aren't all there. This page from the A-5 shop manual, courtesy of Browning, hopefully clarifies a few things.

I've purchased countless Browning A-5's over the years, nine of them are still "in the family," and whack doves and pheasants every year. Though some A-5's were NIB, I have never, ever purchased a used A-5 that was set-up properly. Not one. I guess when all else fails, "read the instructions, dummy" still applies. It seems that some people have the bizarre idea that "A-5's are kickers," when the exact opposite is true. If you believe in physics, they can't kick harder than a pump gun.

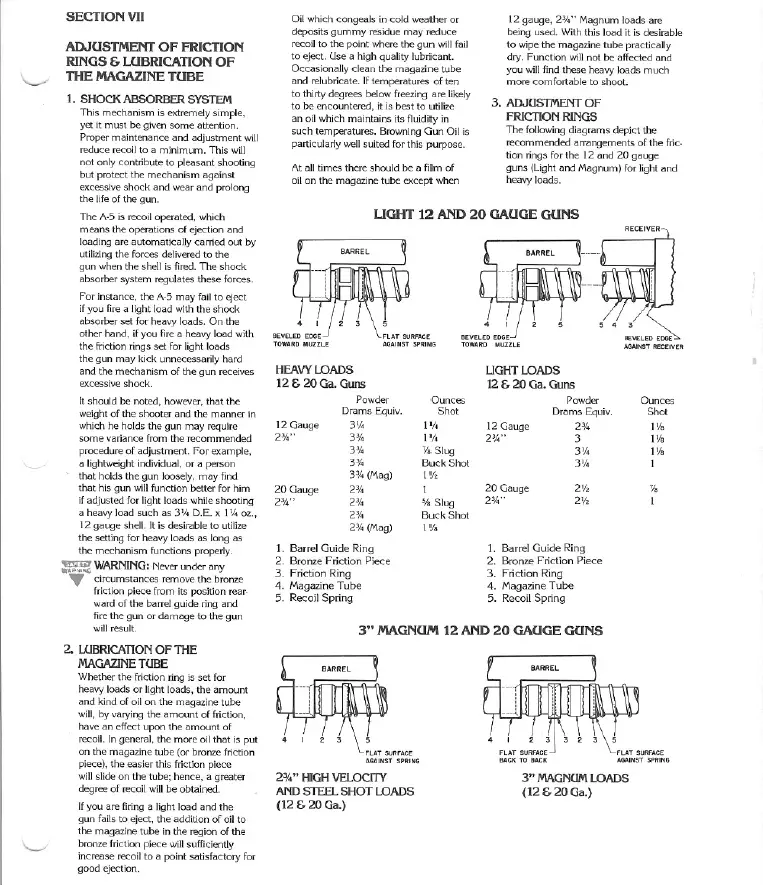

The "improper set-up" I'm referring to is the bronze friction piece and bevel washer. It is simple enough: the beveled side of the bronze friction piece mates with the beveled portion of the barrel ring, always. The flat side of the bevel washer always resides against the recoil spring.

Let's talk A-5 Light Twelve. For the standard 1-1/8 oz. target and dove loads, the bevel washer is against the receiver, its flat side against the recoil spring residing in front of it. Now, you have a small amount of compression applied by the bronze friction piece, and the gun cycles as it should with target loads. For pheasant or "high brass" 1-1/4 oz. loads or heavier, the steel bevel washer is placed between at the bottom of the bronze friction piece, bevel facing the friction piece, flat side (as always) against the recoil spring. Now, the bronze friction piece is forced to squeeze harder on the magazine tube, and the spring is allowed to soak up more of the recoil and slow down the breech. This applies to the standard weight A-5 12 ga. and 16 ga., the Light Twelve, the Light Twenty, and the Sweet Sixteen.

The 12 Mag and 20 Mag versions use two smaller friction pieces and a total of three bevel washers. All reside on top of the recoil spring (a.k.a. forearm spring) for 3" loads, the top bronze friction piece and two bevel washers removed for heavy 2-3/4" loads. Unfolded shell length isn't particularly important: payload weight and velocity determines action function, not a shell length itself.

For some reason, a few folks think that the Browning A-5 recoil spring should last longer than shock absorbers from a 1967 Chevy. As stored, the A-5 recoil spring is always under compression. After several years, there is often a bit of spring set, and that spring should be replaced. An inexpensive item, it is readily available from Brownells. The bronze friction piece does wear with heavy use, and is also inexpensive to replace from Brownells or from Browning in Arnold, Missouri.

Many A-5's, fifty years old (or older) have never ever had any attention paid to this simple arrangement. Any time I buy a used A-5, it gets a new recoil spring and bronze friction piece as a matter of course. A properly set-up A-5 should jam with light loads when set for "high brass" loads, functioning fine with heavy loads or with light loads when set for them.

Now, you have a soft shooter: the barrel should never peen the back of the receiver. So many folks have shot my A-5's and commented that they are real cupcakes compared to their Over/Unders and pumps. They are, and not one of them has a recoil pad. When down in Entre Rios Province of Argentina to duck hunt, one of the local "house guns" was an old A-5. I shot it, and it kicked like a mule! After taking off the forearm, I could see there was no bronze piece, no bevel washer, no nothing. The bird boy who gave me the gun to try explained that "he threw all that stuff away!" It has been shot for 25 years or so like that, never cleaned, and he was proud because "it never jammed." I believe him.

The barrel pounded the back of the receiver like a ball peen hammer with every shot. It never broke a single part in all those years, testimony to the ruggedness of the A-5 design. I'm sure it is still kicking equally hard (very enthusiastically) today. So, I am aware of one A-5 that does kick like a barrel stabbing its way directly to the back of the receiver at full speed, which is precisely what it was doing, and likely still is. He sure loved that old thing, though.

A-5's are said to be "prone to forearm cracking." Well, after something over 50K rounds though A-5's, I've never cracked one. Coincidence? Not really. Some 0000 sandpaper and a few moments to make sure the barrel does not contact any part of the forearm wood through the cycle, and you are golden. Finish with a few drops of Tru-Oil to seal the inside of the forearm, and you're done. Just keep that forearm nut tight; it's the only thing that holds the barrel on. Browning has beefed up that forearm nut area twice over the years. A glance at a Belgium made A-5 and a more recent Miroku made A-5 forearm will show the difference.

They are fabulous guns. Minimal attention to simple things like bronze pieces and recoil springs keeps them humping along comfortably. Another thing that is too common is over-oiling or even greasing up the stainless steel magazine tube. STP, Mobil One, Breakfree CLP, folks just seem to want to oil something--reducing friction that is supposed to be a source of some friction. Clean and essentially dry does it; just one or two drops of Breakfree CLP or Montana Extreme Gun Oil is all (maybe more than) you need. Browning has long recommended that with hotter loads, an A-5 be operated with its magazine tube essentially dry, just a very light film of oil. It isn't like if a drop of oil is good, a gallon of it must be better. Here's to good humpbacking!

Copyright 2012 by Randy Wakeman. All Rights Reserved.

Custom Search

Custom Search