Shotshell Pellet Behavior

We have wrongfully believed that gauge has much to do with shotgun effectiveness: it doesn't. Nor does bore diameter in general, forcing cone design, or other marketing factors. Nor is shot string either important or a function of gauge. Ed Lowry uncovered this years ago at Olin-Winchester. Lowry published spark shadowgraphs that disproved the commonly held beliefs of shot string. While it was thought that more open chokes had less shot string, the opposite was true.

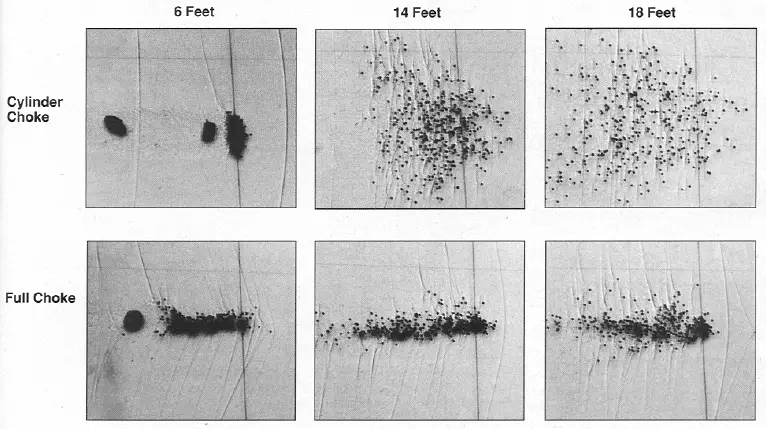

The reason for the confusion was range. At six feet from the muzzle, Cylinder choke appears to be void of much shot string effect and Full choke is already forming the shot string we like to worry about. But, at just eighteen feet, the story changes. Now, the cylinder choke has a longer shot string than our full choke and it just gets worse from there. The reason was simple, but yet was overlooked. The leading wall of pellets in the full choke created turbulent air, turbulent air that allowed the following pellets to more easily pass through. It was simple wind drafting, but it allows full choke shot clouds to have much shorter shot strings than open chokes down range.

The way shot strings are referred to, it sure sounds they are a "string." They aren't. Rather than being evenly populated, the bulk of the shot remains in a relatively small length. It is the leading edge of the shot cloud that breaks the clay or drops the pheasant, the small number of pellets that arrive later aren't very important. Lowry persisted, looking at not the clumsy term of "shot string," but what the point really was: pattern thinning at range, on direct crossing shots, due to the theory of shot string.

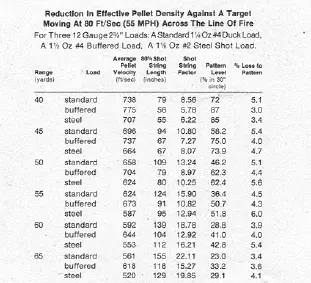

Lowry was able to show that the pattern percentage loss due to the myth of shot string effect under the worst conditions, 55 mph ducks moving across the line of fire at 65 yards, was only 3.4 to 4.1 percent. Trivial compared to shotshells themselves, that can easily vary in pattern percentage 10% or more from shot to shot. The greatest loss was with steel, not with lead, and buffered lead loads proved substantially superior to regular lead loads as well. Lowry also discovered that shot string was not just a matter of choke, but had little to do with gauge. It was a matter of how cleanly the shot was released from the wad, more than the gauge. The two most important factors in pattern performance remain the choke itself and the quality of the shotshell.

This isn't to say that gauges don't matter at all, within reason, they do. But, not much, and not in the way we think. We can't have more pellets in a pattern than we move out of the muzzle in the first place and that is the limitation of the gauge. We also can't have more downrange velocity than we start with, so that too is a limitation of the gauge.

Lowry reasoned that if shot string was due to variations in shot size and shape, then using 1/8 inch precision ground, hardened steel balls (bearing grade) would give a very short shot string. So, that's what they tested, funded by John Olin. It was true to a degree, as the 80% shot string lengths at 40 yards averaged 50 inches from both cylinder and full-choke barrels. But, not by much, as #4 buffered lead yielded a 56 inch 80% string and #2 steel produced a 55 inch string at the same distance. The way the individual pellets left the column in the first few yards of travel was a more significant factor. Pattern thinning due to shot string was still only 3% at 40 yards for the buffered lead, 3.4% for the #2 steel under the worst conditions as shown by the Lowry team test results. Use of hardened, precision ground steel balls did not significantly improve things.

If there is good news, it is that gauge, bore diameter, forcing cones, and so forth don't matter from a practical perspective. Nor does chamber length, even though a 2-3/4 in. unfolded length shell tends to pattern more efficiently in a 2-3/4 in. chamber than a 3 inch or 3-1/2 inch chamber, it isn't enough to matter. Only the specific shell and the specific choke control pattern quality significantly. If there is "bad" news, it is just that the selection of choke and shotshell for a specific application remains a trial and error process we have to conduct for ourselves at the pattern board.

Copyright 2011 by Randy Wakeman. All Rights Reserved.

Custom Search

Custom Search