Defining the "Sealed Action" Muzzleloader

A lot of hay has been made, or least has attempted to be made in ad-brags, about inline muzzleloaders that have "sealed actions," are "weatherproof" (what kind of weather?), and so forth. Like many claims, things are seldom what they seem. The above photo is a frame grab from my firing of the now mercifully discontinued Remington 700ML. With the violent, scope baking spew of primer compound from the Remington, it should be no surprise that scope finishes can be quickly removed, and some of the resultant spewage makes proper cleanup of your muzzleloader a pain. In fact, when last shooting a pair of Remington 700's with 209 ignition-- it felt like flaming sand particles were searing themselves into my face. I audibly groaned with each shot. Believe me, you will have no problem forgetting to wear eye protection with one of these filthy monsters.

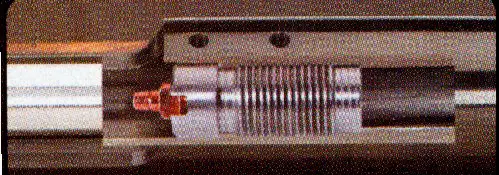

A lot of progress has been made from that approach. The Knight red plastic jacket is an improvement. Here's a look at a cutaway of the Knight plastic jacket breech plug:

Here is the Knight 209-primed "full red plastic jacket" being fired:

Examination of the Knight red plastic jacket approach (Knight Disc Extreme depicted above) shows that while 209 external blowback is diminished, it remains. The Knight breechplug has a nipple that the 209-primed red plastic jacket is pressed onto. Whatever hot gas can make through that nipple does just that-- the excess has no where to go, except to escape around the nipple-- coating the Knight bolt action and the scope. After ten to fifteen shots, so much grit is deposited around the bolt, the action being to be difficult to work. This is certainly a "weatherproof" approach, but obviously is neither fully sealed internally or externally.

Other techniques

have joined the fray: the NEF / H & R "Sidekick" uses a

"209 primer holder" that is designed for multiple shots rather

than the "one shot" approach recommended by Knight. The NEF

primer carriers have a tab on their side to show that the Sidekick is

primed (or could be primed), but quickly become greased up with

primer residue, as does the inside of the radically large breechplug in

from of it. Being of a harder durometer material than Knight full red

plastic jackets, it is a compromise approach. It is essentially weather

proof (a term that leaves wiggle room), cuts some of the external

blowback, but does not do as good a job as the Knight jackets in either

regard. Primer compound quickly coats the inside of the breechplug, and

some of the crud to lesser extent may migrate past it into the NEF pinned

together action. It is not the best, not the most advanced method, but

is adequate for most field applications taking into consideration the

entry level price point of the NEF H & R rifles.

In 2002, the T/C drop-action Omega appeared, killing most of the external blow back with the end cap. As experienced Omega shooters already know, a few minor sparks can make their way through the cap where the hammer strikes, and some small amount of primer residue can make a path below the barrel requiring removal of the barreled action from the stock to get at it. It is effectively weather proof, though, requiring no peculiar plastic consumables. Close to "externally sealed," internally most of the mess is caught by the barrel end cap where it can easily wiped out. The 209 primer is not guided, so it tends to lay in the center of the breechplug. Once in a while, I've stuck primers in the breechplug as there is no extractor-- removing them with a set of needle nose pliers. This is, to be fair, a rare occurrence. It remains weatherproof, mostly externally sealed, but not internally sealed.

The

standard T/C Encore has a straight built in extractor, using the same

breech plug as the Omega-- so, the primer sticking potential is eliminated.

Some crud does get back into the action, varying by gun, that is removed

by disassembly and use of Brake-Kleen on the action from time to time.

As Doc White observed, the Encore leaks like a sieve from a "waterproof

sense" where the steel barrel mates against the steel action, swinging

into place by use of the Encore / Contender hingepin for alignment. It

is essentially externally sealed, but a long ways from being internally

sealed. Yet, in a tangible real-world sense, it is essentially field "weather

proof," does not stick primers, and requires no plastic thingies

to operate.

The Savage 10ML-II currently is the only true sealed action system in muzzleloading, both externally and internally. The 209 primer is controlled both in feed and extraction as it is attached to Savage's patented steel bolt that features an integral steel horse shaped primer holder. A primer cannot possibly stick into the breechplug. As you can see from the picture of the 10ML-II breechplug above, with a W209 primer on top of it, the Savage approach uses no nipple as in the Knight technique, nor is the primer allowed to drop completely into the breechplug-- flopping around like a piece of rice in a Chinese bowl as in the T/C Omega. Only a portion of the primer enters the Savage breechplug (about 25%), as the primer is held against the breechplug by the Savage bolt. Upon firing, the primer slightly puffs, creating essentially a perfect gas seal. That why the Savage bolt is not disassembled for cleaning-- it isn't designed to be, as all the primer compound is contained inside the breechplug due to the superior seal. As it contains the spent primer material inside the breechplug, that is why the 10ML-II primer should have the primer carbon drilled out after every 100 shots for best performance. This is the hard crud that never enters or coats your Savage 10ML-II action or bolt or even the barrel. The grit that makes a Knight bolt action hard to operate after ten or so shots does not form on the Savage despite all day range use. As the primer is help against the breechplug deep in the well of the barrel, you have a weatherproof system that qualifies as both a truly externally and internally sealed action.

The seemingly eternal fight against the Triple Se7en crud ring (no issue with the Savage 10ML-II and smokeless) has led to some rediscovery. Hodgdon often uses T/C Omega's to test for crud ring build up. Hodgdon reports that the heaviest fouling is with a new Omega breechplug that has about a .029 in. flash hole. After 100 shots or so, the T7 crud ring is not quite as bad-- as the T/C Omega breechplug erodes quickly, the flash hole opening up to .034 in. or so.

This verifies the discovery made by Henry Ball some 14 years ago-- so now you know why the patented Savage 10ML series ventliner (it is simply a replaceable flash hole!) is closely guarded by Savage Arms, and why it should be replaced every 100 shots to insure brand new gun performance, without buying a whole new breechplug.

That Henry Ball fellow sure is clever, as is Savage Arms. So this completes a look at a few of the so-called "sealed" and "weatherproof" muzzleloading actions out there-- now, perhaps you can better appreciate the tangible differences.

Copyright 2006 by Randy Wakeman. All Rights Reserved.

Custom Search