Dealing with Steel Shot Part Two: Effective Countermeasures

We know the most significant problem with steel shot (99% iron) is its horrible density. The density problem of steel as shot material can not be overcome. To achieve the same ballistics with steel as with #6 spherical lead, it takes #2 steel to approach it, #1 steel to exceed it. The old “rule of two,” just going up two shot sizes and calling it good, is a ridiculous notion, for even going up four shot sizes does not quite do it. However, we can exploit what is good about steel: its sphericity, and its ability to maintain sphericity under the crushing forces of set-back. Expensive, precise, long term laboratory work by Winchester Research told us the tale.

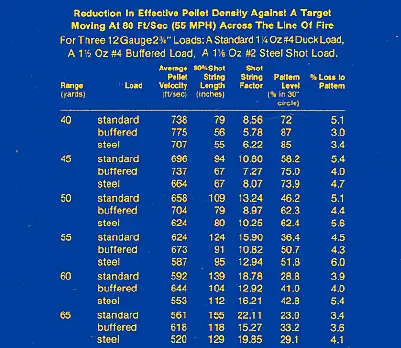

While the point of this series of tests was to document reduction in pattern density due to shot string (the worst was steel at 55 yards, still only 6%), it showed us far more. It revealed how very important sphericity was. The best patterning efficiency load was buffered lead at 87% at forty yards, with steel practically as good at 85%. Unbuffered lead, lead that deforms easily upon firing, managed only 72% at 40 yards. Just 10 yards out, things got a lot worse for unbuffered lead.

At 50 yards, it was 62% and change for buffered lead and steel, with regular

lead plummeting to a 46.2% pattern efficiency. Steel, due to its sphericity,

holds pattern percentages far better than unbuffered lead loads. Lead

shot does not tolerate high velocities well. Patterns spread in concert

with higher velocities, regardless, but steel tends to spread less and

deformation during firing is not an issue. While there are limits due

to standards (CIP maximum is 1410 fps) and the increased recoil that comes

with higher muzzle velocities, 1400 fps steel is of benefit. Steel does

not give great patterns as often assumed, but does respond to choke. A

Trulock Precision Hunter extended choke tube, for example, is both steel

and tungsten rated up to "Improved Modified" designation. We

aren't stuck with the sloppy factory notion of "modified = full"

at all, unless we want to be.

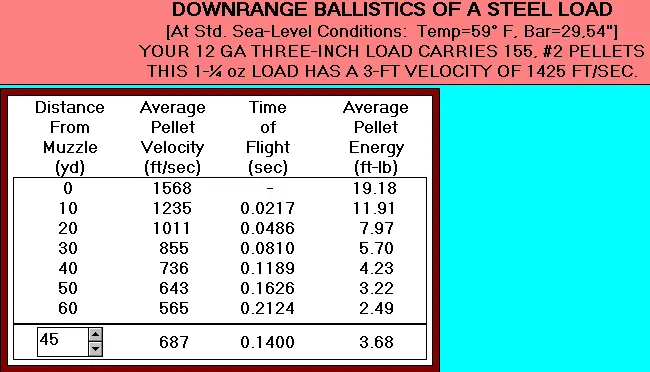

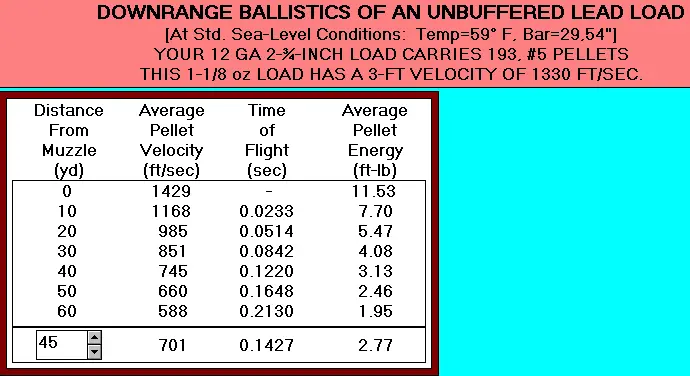

Above, I'm using a faster #2 steel load, 1-1/4 oz. payload, compared to a lighter, soft, unbuffered 1-1/8 oz. #5 lead load. Yes, I'm trying to make steel look as good as possible. While the pellet count of the steel load is deficient, 155 pellets vs. 193 pellets for the lighter payload lead load, steel has equal or better strike velocity to 30 yards. It trails soft lead at 40 yards, but not by much: just a trivial 9 fps.

The unbuffered lead load has 1.99 inches of penetration into ballistic gel at 40 yards; the steel load has a bit less, but still formidable 1.89 inches. While steel cannot compete with buffered lead loads, nor can it compete with Tungsten-Matrix, Nice Shot, or other denser shot materials, it is usable to 40 yards, assuming you pattern your gun with the shells you intend to use, and are convinced that you have adequate pattern density to get the job done cleanly.

As a long range load, it isn't nearly as hopeful. As you can see from the Winchester Research data, at 65 yards you are dealing with about 29.1% pattern, making the poor initial pellet count a factor not easily addressed. The effectiveness of steel, at range, is all built upon spherical form factor. Any non-spherical shot severely impacts strike velocity and penetration . . . and as a generalization, is to be avoided.

Copyright 2013 by Randy Wakeman. All Rights Reserved.

Custom Search