A Simple Way To Select an Aftermarket Screw Choke

Now that replaceable screw chokes have, in large measure, obsoleted fixed choke shotguns in the American market, deciding upon an aftermarket choke tube can be bewildering. It seemed easier when fixed chokes were the norm, as it made it easy for use to assume that just because a barrel was stamped “Modified,” it was going to throw whatever our theory of a modified pattern might be. That's the way it was for the most part when I was younger, modified was good enough for most hunting purposes and since no one I knew ever patterned their shotguns, no one knew or cared about patterns. Modified worked, at least well enough, and that was mostly that. If you shot skeet, your barrels were conveniently stamped “Skeet” and for longer range waterfowl hunting or casual trap, you'd just get a gun with a barrel marked “Full.” The old “dime trick” was well-known. If a dime didn't go into the muzzle of your 12 gauge shotgun's bore, it was supposedly a full choke, at least with some kind of shell.

The dime trick meant little. The general standard for 12 gauge American barrels has been .729 in., but that has always varied. A dime is 17.91 mm, or .7051 in. Based on that, a .025 in. constriction allows a dime to pass, yet constrictions of .030 in. - .040 inch are typically full pattern percentage chokes, depending on shell. It has always been a mess, ignorance is bliss, what you don't know can't hurt you, etc. For years, though, it was accept what a stamping is on a barrel was good enough for many. Our collective ignorance is conveniently supported by a broken piece of clay or a dead duck, but live pigeons were whacked and ducks were taken long before Fred Kimble introduced his choke-bore shotgun in 1868.

The big variable involved is range. As long as ranges vary there can be no all-around “best” choke, for the largest effective pattern diameter exists only at one range. The more open chokes are the easiest to deal with as in American skeet. A .002 - .004 in. constriction choke is usually all that could be asked for.

For hunting flushing game as well as sporting clays, .015 in. to .020 in. constriction is the most generally usable arena. The better the shot you are, the more you can benefit by tighter chokes. From that standpoint, the standard pattern efficiency comparison of percentage in a 30 inch circle at 40 yards makes no sense at all. If you are shooting at 30 yards, what the pattern is or isn't at 40 yards is unimportant. While the “30 inch circle” is often wrongfully called the “critical area,” that isn't the case. The kill zone of a pheasant is roughly five inches square, and it isn't a perfect circle. That's only 25 square inches. Being off of the kill zone by pointing error is a consideration, but how far off are we? A fifteen inch circle is of course 171.71 square inches, well over six times the kill zone. How many kill zones are we off by?

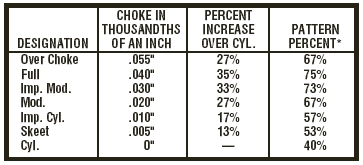

No chart giving patterns at 40 yards in a 30 inch circle can be exact.

This does not take into account the size of the shot, the hardness of

the shot, the payload weight, muzzle velocity, the design of the choke

itself, ambient conditions such as elevation, or the gauge being discussed.

Whoever said the only thing that is predictable about shotguns is that

they are unpredictable had it right. We need to start somewhere, though,

and the above chart serves that purpose. Percentages do not bag birds,

pellets do. So, it is important to also look at the number of pellets

contained in our shotshell loads. In an ounce of lead shot there are approximately

585 #9 pellets, 410 # 8 pellets, 350 #7-1/2 pellets, 225 #6 pellets, 170

#5 pellets, 135 # 4 pellets, and 90 #2 pellets. It should be clear that

to well-populate a pattern takes a lot more #4 shot by weight at 135 pellets

to the ounce than #8 shot at 410 pellets to the ounce.

Pattern density improves with constriction, up to a point. Somewhere around .040 in. constriction is the point where further gains are small, indiscernible, or patterns may decay. Of course the shell used has everything to do with it, no choke tube self-compensates for a shell and shot size. These are only starting points. For skeet, a .003 in. constriction, flushing game to 35 yards, .015 to .020 inch constriction, 27 yard American Trap .030, long range dove or pigeon, .030 to .035 in. constriction are all reasonable starting points. For turkey inside 40 yards: .040 inch.

The above image is a Trulock Precision Hunter extended choke tube. Far stronger than many OEM type tubes, it is made from 17-4 stainless heat-treated to 200,000 PSI, then it is blued (black oxide) so it looks great with blued barrels. Aside from the lifetime guarantee and the industry-leading 60 day exchange or refund policy, it is safe with steel shot through a minimum "Improved Modified" designations or about .025 inch constrictions. An extended choke protects the comparatively fragile crown of your barrel and you don't need to stick your face in front of the muzzle to know what choke tube you have installed. A properly machined choke picks up less plastic fouling, is wear-resistant with hard shot materials. An extended choke such as this never hurts pattern percentages in my experience, but often provides better percentages with less constriction, and better percentages with larger diameter shot or heavier payloads as well.

I suggested that I was going to make this simple. As simple as it gets is measuring the inside diameter of your barrel and screwing in a Trulock Precision Hunter extended choke with a .015 in. or so effective constriction. Within range, it is all the choke you need for casual clays, sporting clays, flushing upland game, decoying ducks, waterhole doves, etc. It won't be the universal choke, of course. Enough folks write and want the "ideal" choke from 20 to 60 yards, which means four different choke tubes.

A choke tube can only do so much. Percentages are all well and good, but pellets get the job done, not percentages. Percentages of what, exactly? Pellet count in a shotshell is a huge factory, something we can change by payload mass, shot density, and shot diameter. Shotshells don't pattern all alike, so invariably we are back at the patterning board, at our ranges not forty yards, if we want a certain shot density at our ranges.

The

reason measuring your barrels is a vital step is that they vary so much.

With the same brand of shotgun, a "B" brand, I've had barrels

of the same gauge vary by .015 inch and more. That means the versatile

.015 in. choke tube mentioned here may be no constriction at all, or a

.030 in. constriction. Unless we measure bore inside diameters of our

barrels, we won't a have a clue where we are starting at.

Copyright 2011 by Randy Wakeman. All Rights Reserved.

Custom Search

Custom Search