Gas-operated Vs. Recoil Operated Autoloaders, Part II

This discussion quotes excepts from a public document, courtesy of the U.S. Patent Office. It is patent US 7,707,923 B2 of May 4, 2010.

Several types of semi-automatic shotguns are known, the operation of which is based on different principles.

GAS-OPERATED

“A

first type of semi-automatic shotgun is that called “gas-operated”.

In such shotgun, the energy of the gases developed by the powder explosion

is exploited. A small part of such gases is drawn from the barrel through

one or more holes, in order to generate an expansion inside a cylinder

closed by a sliding piston. The piston thrust generates, in turn, an impulse

which recocks the mobile masses, ejects the shell, and loads the new ammunition.

The piston thrust is extremely variable as a function of the force of the primary impulse generated in the chamber by the powder explosion. Such primary impulse depends on the gram weight of the cartridge which is fired, where “gram weight” means the mass of the charge of fired pellets, therefore the power of the same cartridge. The mass of the powder charge and the mass of the pellets charge are typically proportional.

The gas-operated device, in order to be able to ensure the required reliability, must necessarily be dimensioned for the operation with those cartridges having the lowest gram weight which can be chambered in the shotgun. Once the device has been properly dimensioned, the variability of the cartridges gram weight and the consequent primary impulse translate in a variability of the recocking speed. The minimum speed is the one which is necessary in order to achieve a safe operation of the weapon when a cartridge having a low gram weight is fired. The maximum speed corresponds to the firing of a cartridge having the maximum gram weight which can be chambered in the shotgun.

However, the high recocking speeds translate in high stresses and, consequently, in a decrease of the working life of the shotgun components. In the whole, this results in a short duration of the same shotgun.

In the more modern gas-operated shotguns, it has been successfully attempted to obviate the problem of the high recocking speeds by adopting shutter or self-compensating valves, which are able to exhaust the excess gas associated to the firing of the cartridges having a higher gram weight.

However,

such valves, or venting systems, involve an increase of the mechanics

and the costs for the shotgun.

Furthermore, the gas-operated systems require a constant maintenance,

since the gas which is vented tends to foul unburnt solids, which have

to be removed after firing a number of shots.

INERTIAL

Another type of semi-automatic

shotgun is the one called the “inertial” type. In this type

of shotgun, the compression and the subsequent relief of a spring that

is arranged between the mobile masses and the shotgun frame are exploited.

The spring compression is caused by the shotgun recoil, and it is exploited

in order to confer to the same masses the required recocking speed.

The shotgun with inertial operation is appreciated because it allows limiting the maximum recocking speeds and the resulting reduction of the stresses of the mechanical parts.

Furthermore, the inertial shotgun is characterized by a pronounced constructive simplicity and a reduced maintenance of use. In fact, not requiring any gas drawing, the inertial device does not undergo any “fouling”. Anyway, the standard cleaning is still necessary for the chamber and the barrel, which are contacted by the firing gas.

In contrast, the low recocking speed, which is intrinsic of the inertial shotgun, may be a problem, especially when the shotgun frame has a high mass, and the fired cartridge has a low or very low gram weight. The low recocking speed translates in a low shell ejection promptness and a high risk of jamming.

Furthermore, the operation of such type of shotgun is highly affected by the user's behavior, particularly by the type of reaction which the user opposes with his/her shoulder to the shotgun stock.”

Though this patent apparently was used to cover the now introduced and

discontinued Beretta UGB 25 and is by Ugo Beretta, it does cover self-loading

shotguns in a far more frank, less flattering manner than most ad-copy.

The excessive bolt speed and associated wear is a potential issue. When seeking the “shoots everything” gas autoloader, the 12 gauge that we might brag handles our wimpy 3/4 oz. reloads is a poor choice for a steady diet of higher intensity loads, with resultant high stress and comparatively short life.

While this discussion is not particularly flattering to gas autoloaders, it also frankly describes the problems of inertial guns, whether a heavy gun, light loads, a combination of both, and as mentioned function is affected by how the individual mounts the gun. In a solid fixture where rearward movement of the gun is eliminated, the inertial action will not function.

While Beretta describes the maintenance of the gas gun as “constant,” that isn't strictly true. Regular cleaning is required, but the intervals vary from model to model and the most important potential benefit of gas operation, softer and more comfortable shooting, is ignored.

The inertial action, along with its predecessors, the long recoil action (Browning Automatic Five) and various short-recoil actions (Double Auto, A500) does shoot cleaner, and requires less maintenance. The inertial action is cheap to make. Whether they are marketed cheaply or not is another matter, but there are comparatively few parts to machine and assemble. The inertial action can be generally a lighter action as well with out much difficulty, due to the complete lack of gas pistons, seals, piston shrouds, action rails, extra valving, etc.

While Beretta sure doesn't seem enthused about either gas or inertial actions, things are not as dire as their comments suggest. The most influential gas gun, the Remington 1100 of 1963, showed off the soft-shooting potential of gas shotguns by virtue of its 8 lb. weight and its gas system. Though a crude gas system by some standards, it improved on its predecessor (the “Dial-A-Matic,” gas regulating cap Model 58) by eliminating load adjustment by the user. It still needs 300 shot or so cleaning, but it popularized the gas shotgun like no other. Note that the "Dial-A-Matic" sometimes called "dial a duck" compensated only for 2-3/4 inch shell variations, like the standard Browning A-5.

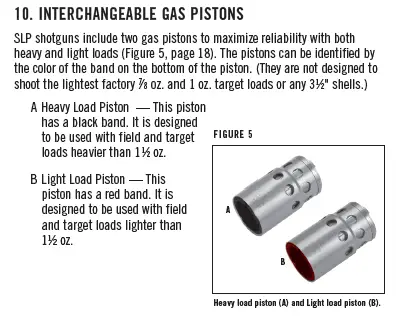

The system used by the Beretta 302 / 303, Browning B-80, and Browning B2000 of changing the barrel as needed from 2-3/4 in. to 3 inch chambering took care of the excessive ejection distances and bolt speed. It was and is a very good system, but changing barrels has lost its appeal. The 1993 Browning Gold (Activ Valve) platform was simplified and improved in 1999 with the Winchester SX-2 that now is the Browning Silver (in 12 gauge). This platform is also the FN SLP; two Active valve pistons are supplied with the SLP and some SX2 Models.

Most folks know whether they are going target shooting or turkey hunting, so getting your bolt speed down to a 4 – 6 foot ejection distance is a good idea to reduce stress, vibration, and get the most out of your gas gun. You have that option with a Beretta 390 or 391 with a secondary gas bleed spring set from Cole Gunsmithing, piston switching with the Gold / Silver / SX2 / SX3 / SLP platform, and the Weatherby SA-08 gives you a pair of pistons with each shotgun for just that purpose. That, and a new mainspring every 6000 rounds or so will help you get the most out of your gas gun, even if it not absolutely needed.

For the first part of this discussion: http://randywakeman.com/GasVersusRecoilAutoloadingShotguns.htm .

Copyright 2013 by Randy Wakeman. All Rights Reserved.