A Brief Visit with George Trulock, Trulock Chokes

The basics of chokes, explained by George Trulock, are as follows.

What is a shotgun choke?

A shotgun choke is simply a tapered constriction of the gun's bore at the muzzle end. The length of this constriction varies between the different shotgun makers but usually is not less than 1.5 nor more than 3 inches. This constriction is normally from .005-.045 (thousandths) of an inch, but in the case of special purpose tubes, it can be as much as .100 (thousandths) under bore size. With screw in chokes you can very easily change the degree of constriction by simply changing the choke. This allows the use of one shotgun for almost all shooting activities.

What are shotgun patterns?

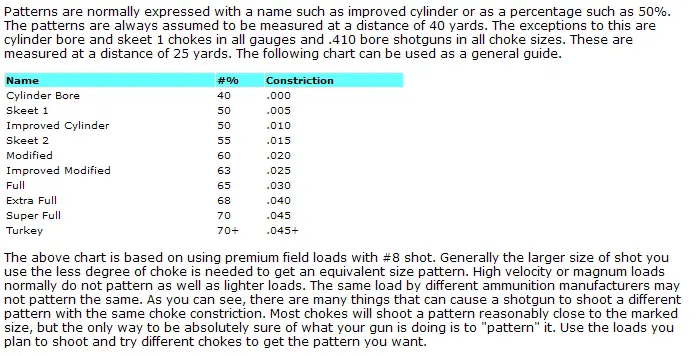

The above chart is based on using premium field loads with #8 shot. Generally the larger size of shot you use the less degree of choke is needed to get an equivalent size pattern. High velocity or magnum loads normally do not pattern as well as lighter loads. The same load by different ammunition manufacturers may not pattern the same. As you can see, there are many things that can cause a shotgun to shoot a different pattern with the same choke constriction. Most chokes will shoot a pattern reasonably close to the marked size, but the only way to be absolutely sure of what your gun is doing is to "pattern" it. Use the loads you plan to shoot and try different chokes to get the pattern you want.

What chokes do I use with steel, bismuth or tungsten alloy shot?

Steel Shot

As a general rule

when switching from lead to steel shot you would use a choke with one

full degree less constriction.

If you want a full pattern with steel use a modified choke.

If you want a modified pattern with steel use an improved cylinder choke.

If you want an improved cylinder pattern with steel use a cylinder or

skeet choke.

Do not use any choke tighter than modified constriction with steel shot

unless the choke is specifically marked for use with steel shot.

Bismuth Shot

Use the same choke you would use with the appropriate size of lead shot.

Tungsten Alloy Shot

There are several different alloys available. These can vary to a large degree in their level of hardness. When using factory chokes I suggest you use nothing tighter than full choke unless it is approved for tungsten shot.

As a general rule most Trulock chokes are rated for Hevi Shot, Hevi 13, Federal Heavyweight and Winchester Hi Density tungsten alloys.

Which Shotgun Bore Diameter Gives The Best Pattern?

I am often asked the above question by people who are interested in purchasing a new shotgun. They reason that if a specific bore size inherently gives better, that is more even patterns, then it makes sense to purchase a shotgun with that bore diameter.

Shotguns that were made in the U.S.A. were for many years all of the same nominal bore diameter of .730 (plus or minus the tolerance of the individual manufacturer) as the U.S. standard for 12 ga was .7299. With the rise in popularity of foreign shotguns such as Beretta we were introduced to smaller bores running in the nominal .721/.725 diameter. Stan Baker to the best of my knowledge was the first to do extensive experiments with backbored barrels (the process of enlarging an existing bore diameter) taking the 12 ga bore up to a nominal 10 ga diameter of .775. Some time back Browning added a new choke design to their line which they named Invector Plus to differentiate it from their original design called Invector. The new chokes and the barrels were based on a nominal .740 bore diameter. I believe that Browning was the first company to offer a factory barrel with a bore diameter that was significantly larger than standard. Currently most of the major shotgun manufacturers offer at least some models with bores larger than their “standard” bores. Some have gone totally to a new larger bore. The results of this are that today’s shooter has a very wide range of bore diameters to choose from.

Pulling from my memory I can recall the following nominal 12 ga. bore sizes. These may not be exact numbers as each manufacturer has plus and minus tolerances. Some of the below numbers have been rounded when converting from metric measurements and some for my convenience.

.725 in., .730 in., .733, .735, .740, .745, .774 inch

Now that you have all of the background information, you can get my answer.

I have always been able to obtain the pattern that I was looking for within reason (no 100% patterns at 80 yards) with all of the above bores by patterning with different chokes and or shells. I have had shotguns on occasion that took quite a bit of work to obtain the pattern I wanted but this has never been limited to a certain bore size as they have always been a random mix.

George Trulock

Copyright 2014 by Randy Wakeman. All Rights Reserved.

Custom Search